2025/06/03 update

Page Contents

AA Wheels & Rim-Flanges

Section Contents – AA Wheels & Rim-Flanges

Overview

Ford sold the AA wheel and wheel rim-flange as separate parts only. Both parts were required for tire installation.

Wheels were dipped, gloss-black enamel as the stock finish. Fleet owners could special order any color of wheels if they were willing to pay for the service. The color could have been non-Ford colors. These wheels were painted over the stock finish.

The June 1931 Indianapolis Service Letter establishes a uniform price list for any commercial paint requests. Painted wheels were to be charged $1.00 each as of that date.

Rim-flanges were cadmium plated. Fleet owners could have the cadmium plated rim-flanges painted over with special colors as can be seen in various Ford archive photographs.

Throughout production here were six wheels and two rim-flanges used with the AA-chassis. The AA Wheel & Rim-Flange Gallery shows examples of these.

Two of the wheels had more than one design giving a total of nine possibilities. Refer to the AA Wheel Table for descriptions and usage dates of these nine possibilities.

Additional wheel identification can be found in AA Wheel Notes and AA Wheel Dimensions.

Throughout production here were three designs of the rim-flange (i.e. split lock ring) used with the AA-chassis. These designs were inter-changeable. Wheel Rim-Flange Designs provides details.

AA Wheel Table

AA Wheel & Rim-Flange Gallery

AA Wheel Notes

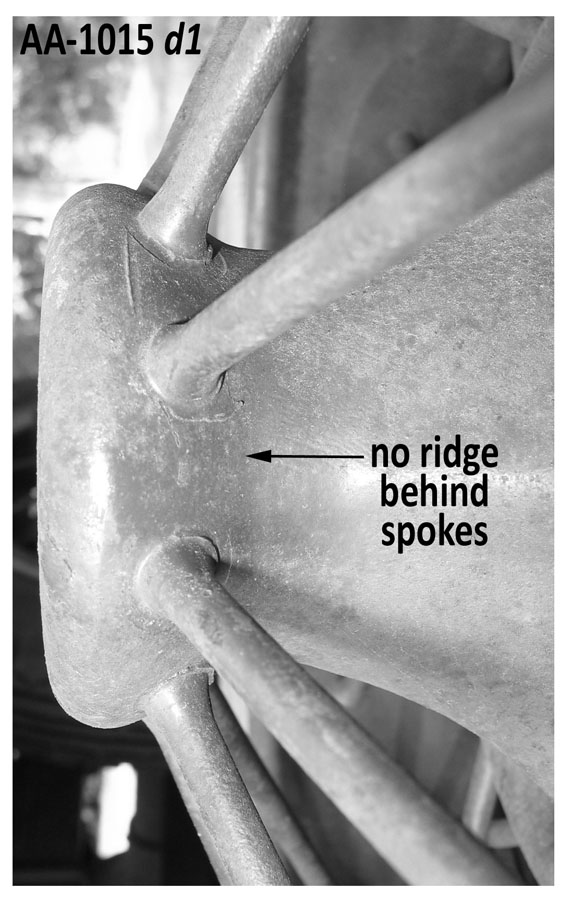

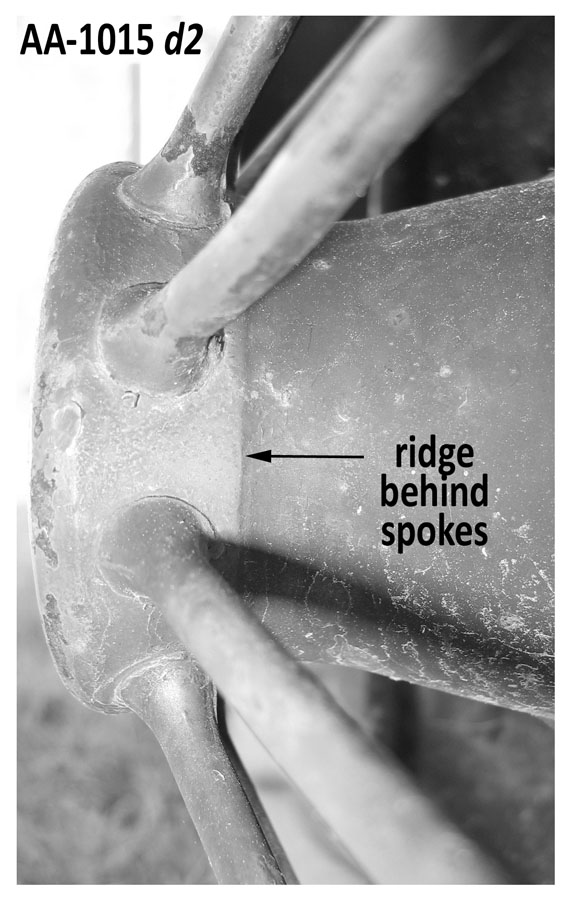

AA-1015 – This steel spoke wheel had two designs as shown in the Notes Gallery below. This gallery also shows the Firestone stampings found on the rim. There may have been other manufactures.

AA-1015-B – Firestone and Cleveland Weld stamping have been found on this wheel (see Notes Gallery below). There may have been other manufactures.

AA-1015-C – This wheel had four designs as follows:

d1 – 1/1930 – Initial design was stamped with Budd part C-18596.

d2 – 4/1930 – Made heavier in the bolt flange area and was stamped with Budd part C-18596-H.

d3 – 1/1931—4/1931 – The wheel offset was increased by 1/8″ and was also stamped with Budd part C-18596-H. This change gave a 1/4” additional distance between dual tires.

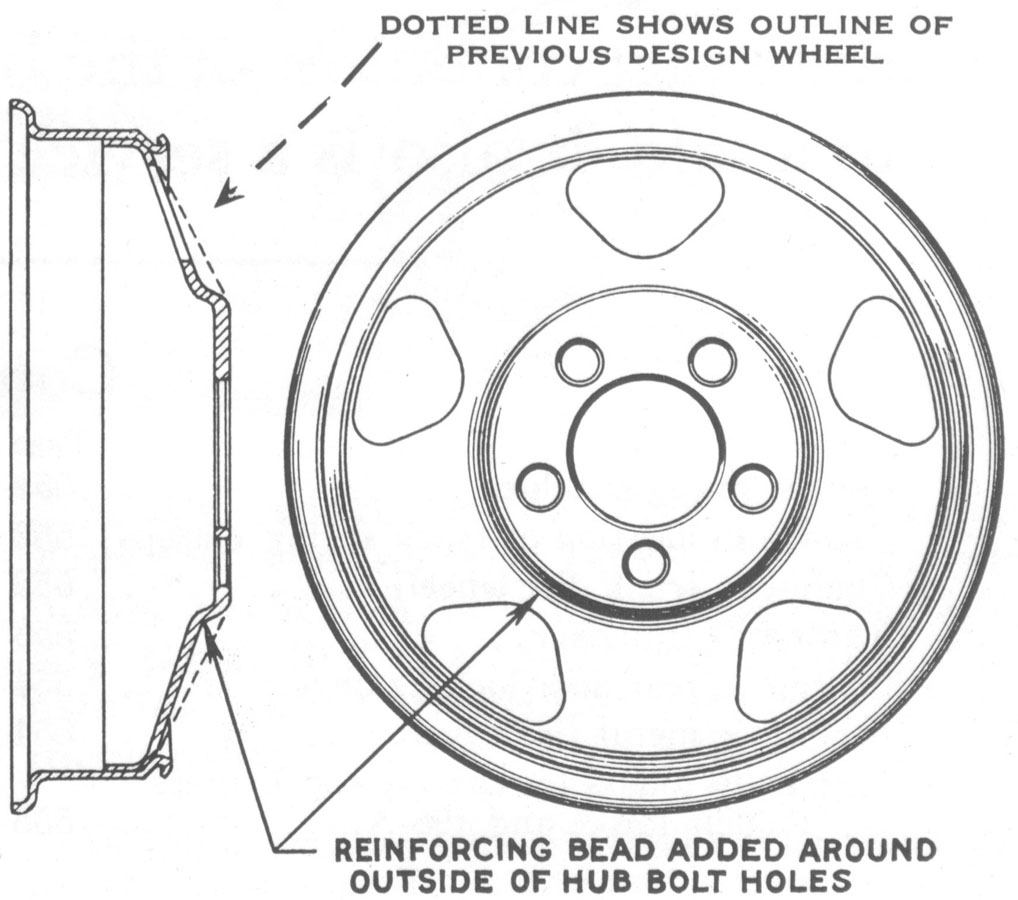

d4 – 1/1931 – Reinforcing bead was stamped around the outside of the hub bolt holes (see notes gallery below); stamped with Budd part C-23597. This wheel had the same offset as d3. AA’s have been found with a mix of d3 and d4 wheels during the 1/31—4/31 changeover time.

For all designs of the AA-1015-C wheel, the production month and year was stamped on each wheel (like “2-30” for February 1930).

See the Notes Galley for stamping examples. The Budd part ID was stamped above the date. Stamped between the next pair of hub bolt holes:

- On C-18596 and C-18596-H wheels “BUDD WHEEL CO.” over “DETROIT U.S.A.”

- On C-23596 wheels “BUDD WHEEL CO.” over “MADE IN U.S.A.”

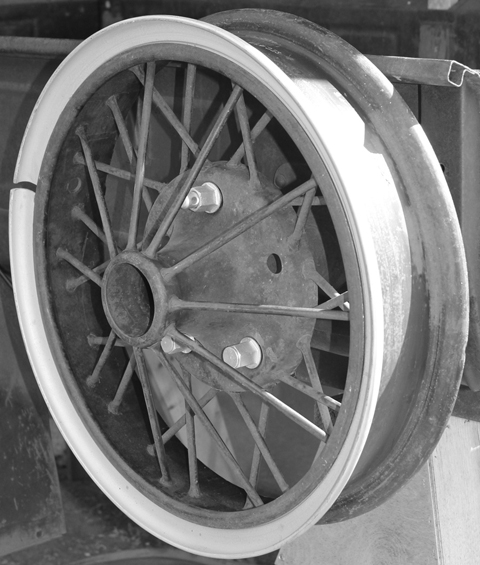

AA-1015-E – This 20” steel spoke wheel was used as optional equipment for body types 270-A, 275-A, 280-A, 285-A, 290-A, and 300-A. They had a larger bolt pattern and required special hubs and drums. These wheels may have been made standard equipment for some of these body types at some time in 1931.

AA-1015-F – This 18” disc wheel was used from 7/1931—1932 as special equipment. It allowed for single rear wheel use with dual wheel load capability. It was used to replace the rear and spare wheels only.

Note that an adapter plate was made available through service for early 1930 single rear wheeled trucks which had “scalloped” hubs. This adapter plate was introduced to help prevent wheel breakage on these trucks due to the initial rear hub design. Dual wheel inner nuts were used to attached the adapter plate to the hub and dual wheel outer nuts held the single wheel against it.

AA Wheel Notes Gallery

AA Wheel Dimensions

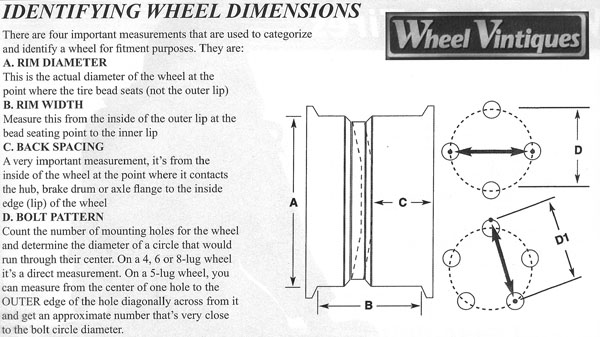

Following are four measurements which can be used to define the AA wheels:

- Rim Diameter – This is the actual diameter of the wheel at the point where the tire bead seats (not the outer lip). 18” for AA-1015-F and 20” for other wheels.

- Rim Width – This is the distance from inside-to-outside of the rim at the tire bead seating points. 3-1/2” for the 20” wheels. Unknown for the 18” wheel.

- Back Spacing (wheel offset) – This is the measurement from the inside of the wheel at the point where it contacts the hub to the inside edge of the wheel. The offset is 2-1/2” for AA-1015 and AA-1015-B wheels. The AA-1015-C wheels have a 6” offset. Offset is not knows for the AA-1015-F and E wheels.

- Bolt Pattern (wheel bolt circle diameter) – For the AA (with its five wheel bolts) this is the distance from the center of one wheel bolt to the outer edge of the wheel bolt diagonally across from it (gives an approximate value very close to the bolt circle diameter). 8” for AA-1015-E and 6-7/8” for other wheels.

Wheel Rim-Flange Designs

The demountable wheel rim-flange (i.e. split lock ring) was cadmium plated. It was a TT carryover part.

For the 20″ AA wheels the rim-flange was part AA-1099. It was changed to AA-1099-A in July 1931 when the AA-1015-F 18″ wheel was introduced. The rim-flange for the 18″ wheel was part AA-1099-B.

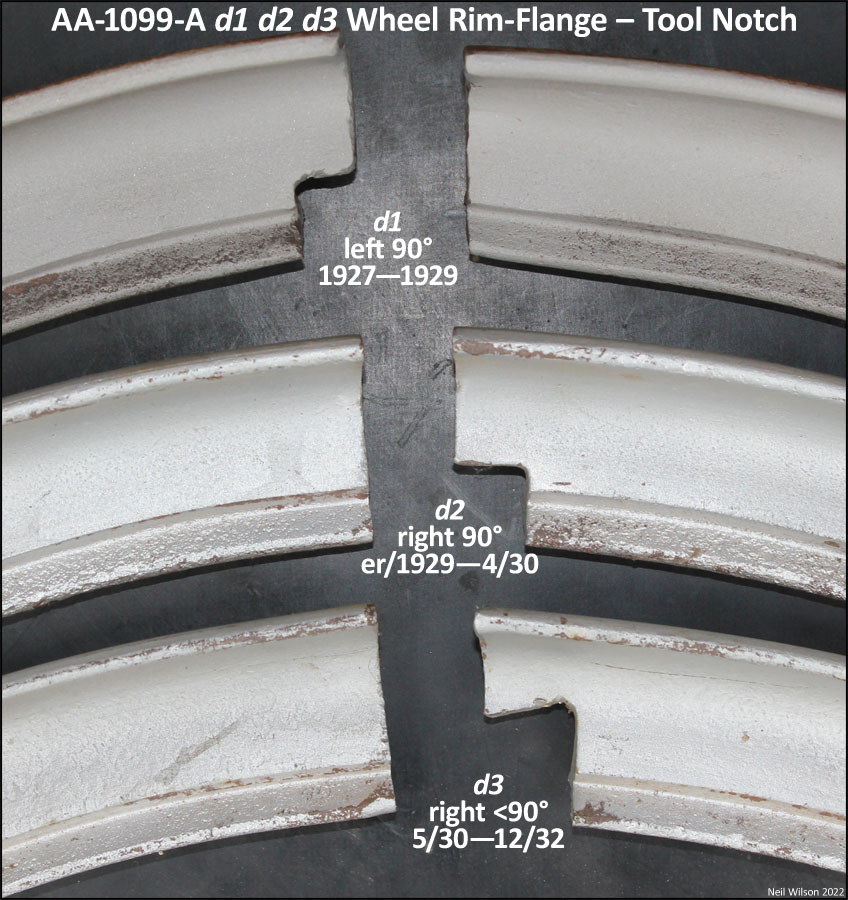

The rim-flange for the 20″ wheels had three designs (d1—d3). These designs were inter-changeable. The design changes involved the removal tool notch at the split of the rim-flange (see photograph below).

Note the overlap in d1 and d2 production dates indicated in the photograph. Also note that original un-installed rim-flanges had almost no space at the split (not as shown in the photo).

Rim-flange stampings for each design were as follows (the top half of the stamping was sometimes not visible due to poor stamping):

d1 – “HAYES 30/5”

d2—d3 – One of two identifications:

“FIRESTONE ☆ 30X5 ☆ DT ☆☆☆”

“☆FIRESTONE ☆ 20X5 * DT ☆☆☆”

The design of the AA-1099-B rim-flange for the AA-1015-F 18” wheel had the same notch design as the 20″ wheel d3 flange. Stamping information is not currently known.

AA Wheel & Carrier Nuts

Section Contents – AA Wheel & Carrier Nuts

Overview

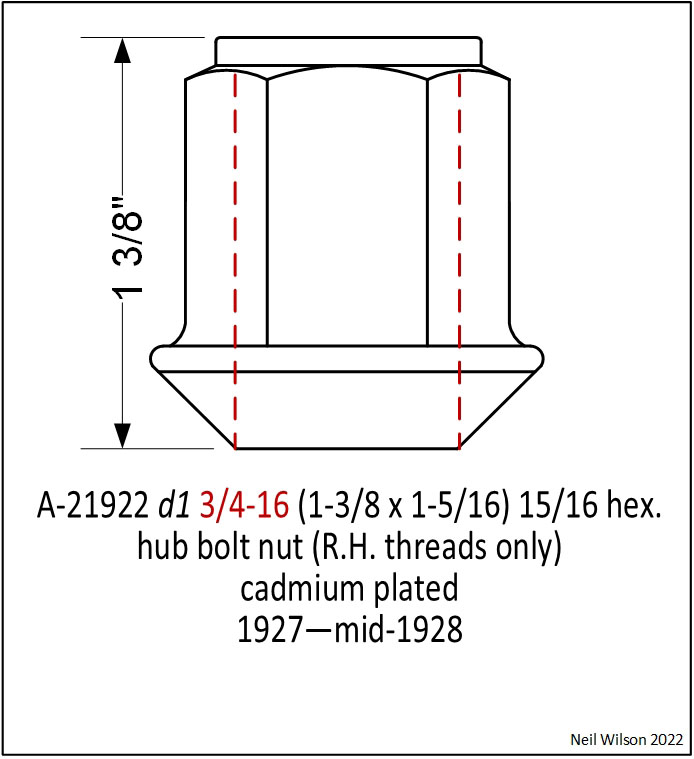

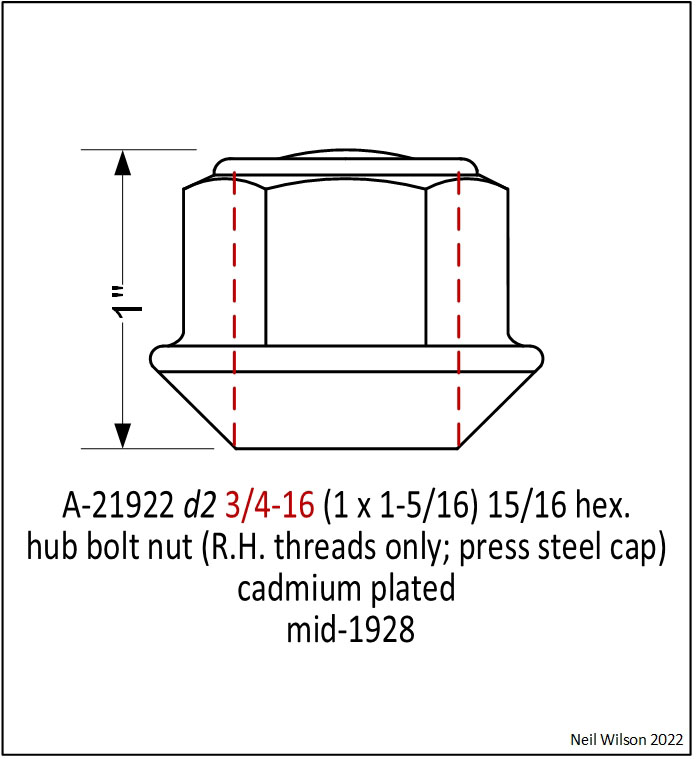

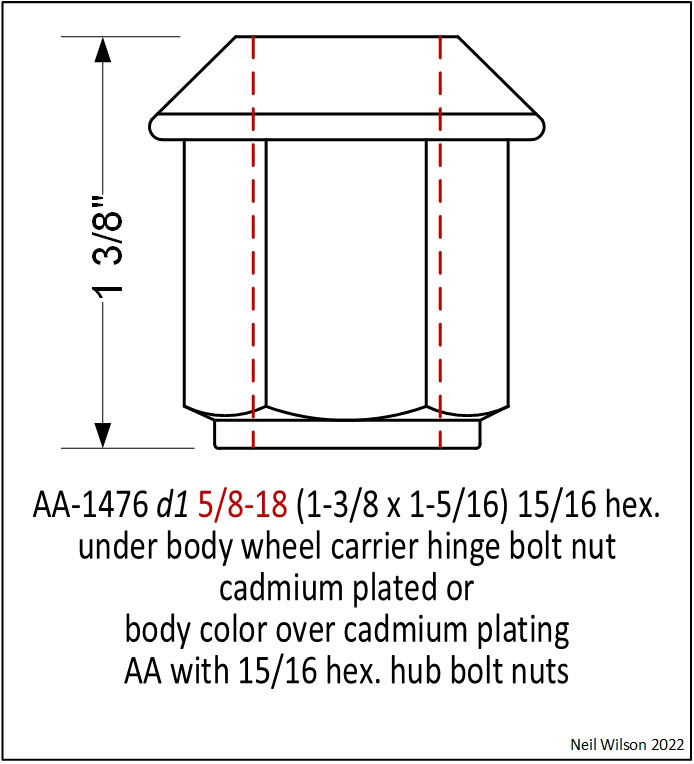

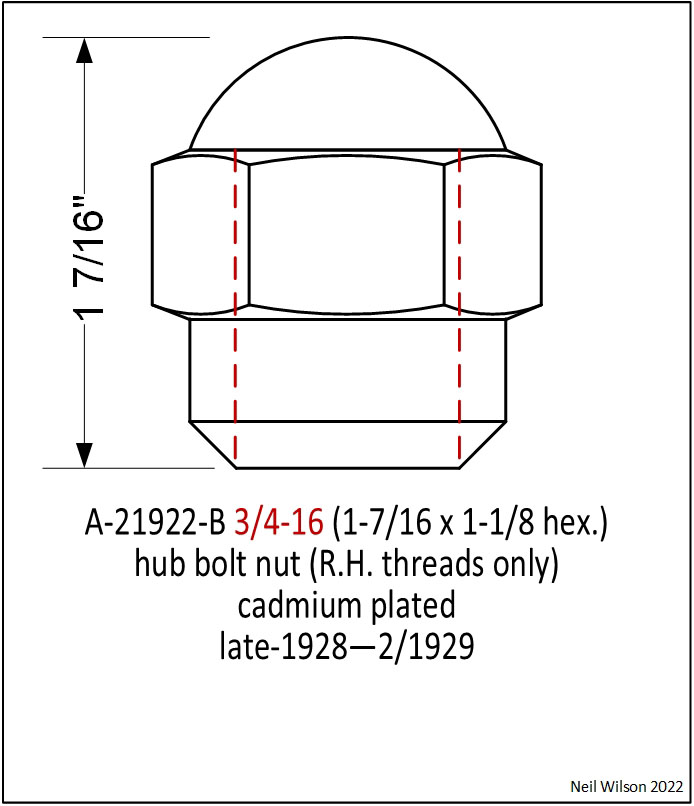

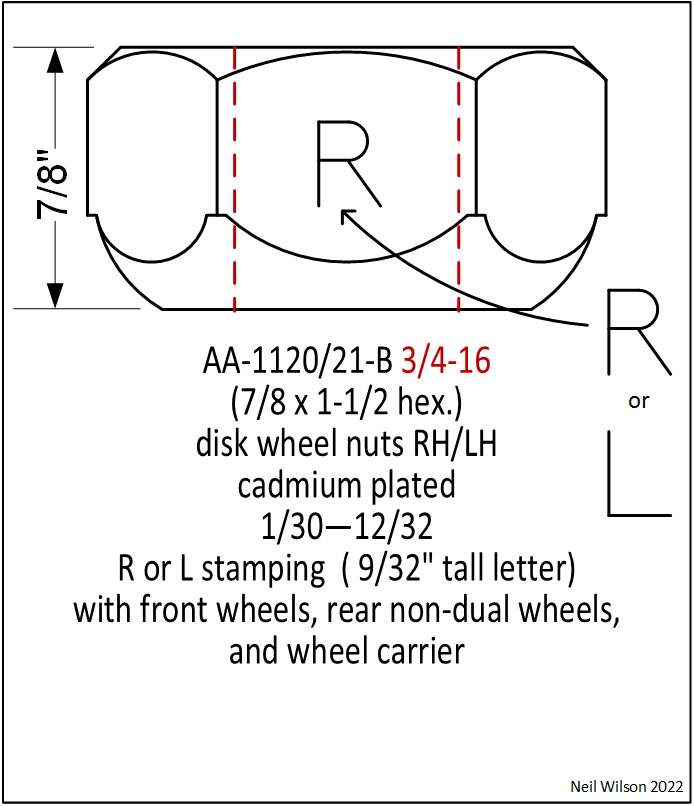

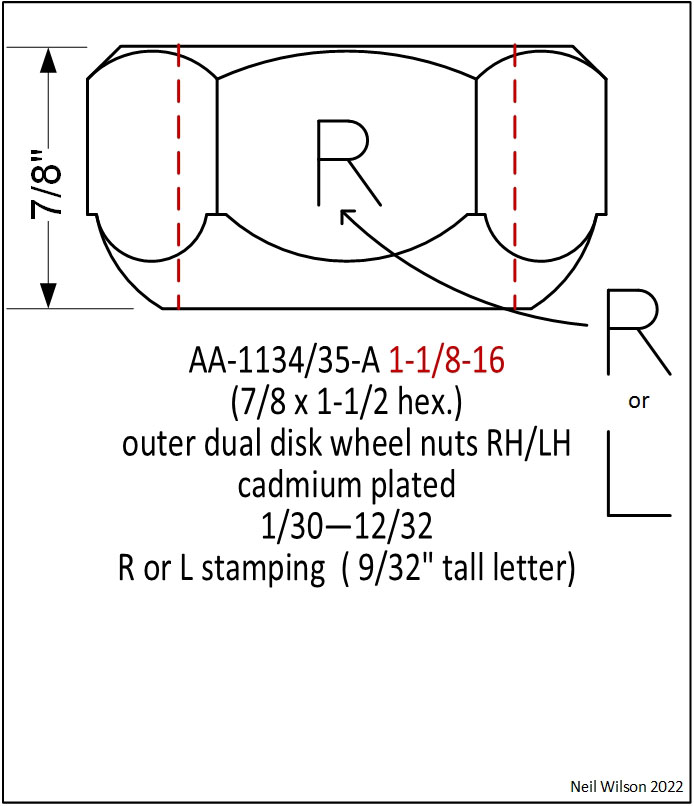

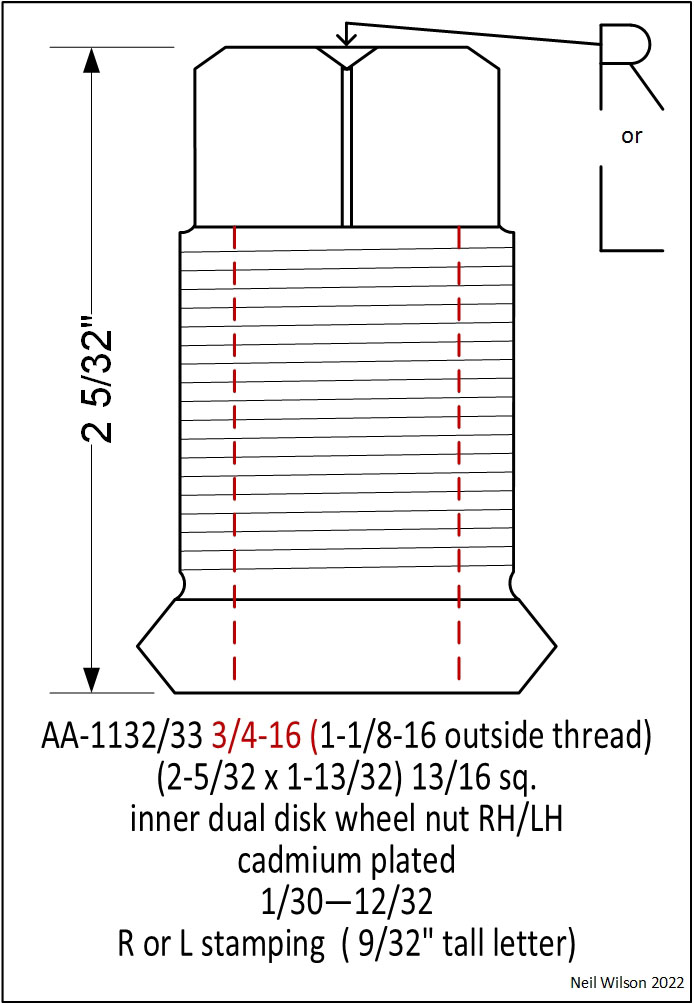

Wheel nuts are commonly called “lug nuts” today, Ford parts lists first used the name “wheel bolt nut” and then switch to “hub bolt nut” for the 1928—1929 AA-chassis. The name “disc wheel nut” was used for the 1930—1932 AA-chassis. On this site, the name “wheel nuts” is used except when listing a part from the Ford parts lists.

All wheel nuts were originally cadmium plated. Until mid-February 1929, AA wheel nuts were all right-hand threaded and were not stamped with an “R” (indicating right-hand threads).

All wheel carrier wheels were installed with the right-hand nuts used to install ground wheels.

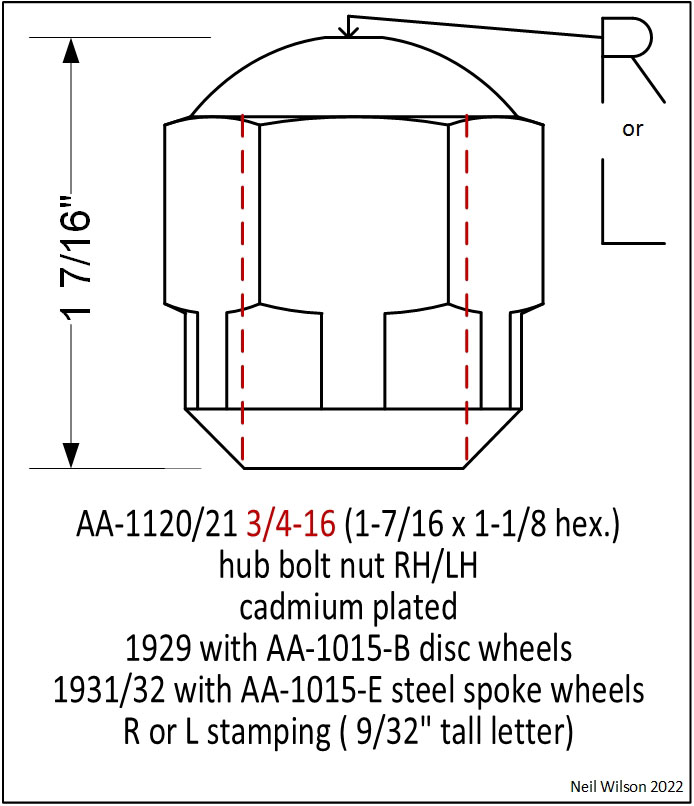

Starting mid-February 1929, wheel nuts were right-hand threaded on the right side of the AA-chassis and left-hand threaded on the left side of the AA-chassis. These wheel nuts were stamped with “R” for right-hand or “L” for left-hand threads.

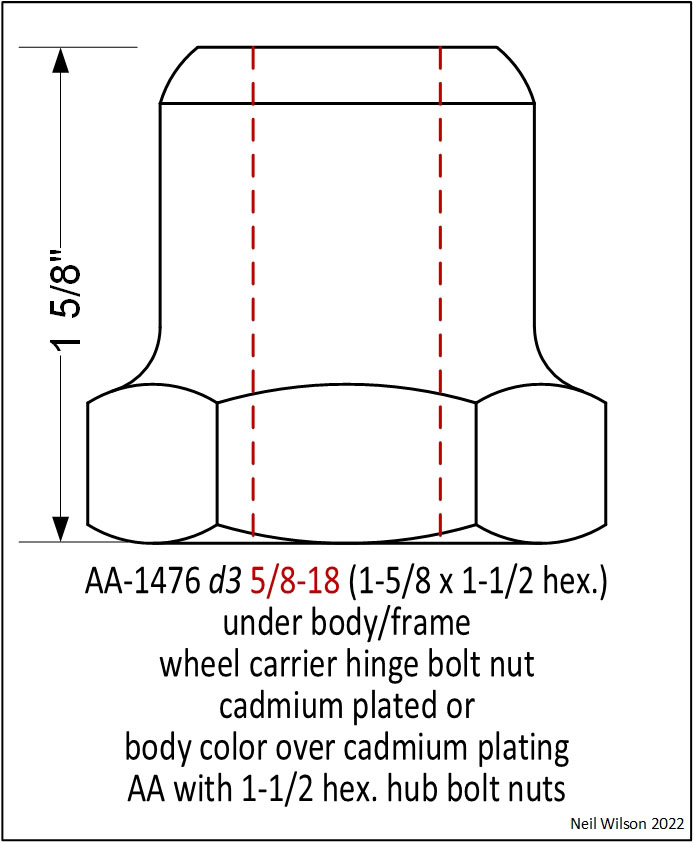

The Ford supplied AA tools could have been used to remove/install wheels without the need for additional wrenches. For a given AA-truck, the following nuts all had the same hex. size:

- ground wheel nuts

- carrier wheel nuts

- side wheel carrier lock nut

- under body/frame wheel carrier hinge bolt nut

Wheel & Carrier Nuts Gallery

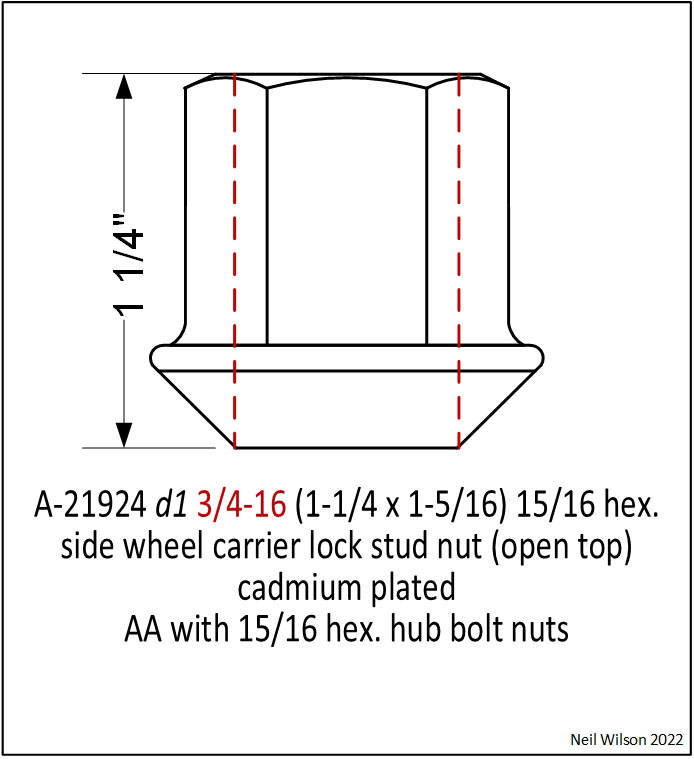

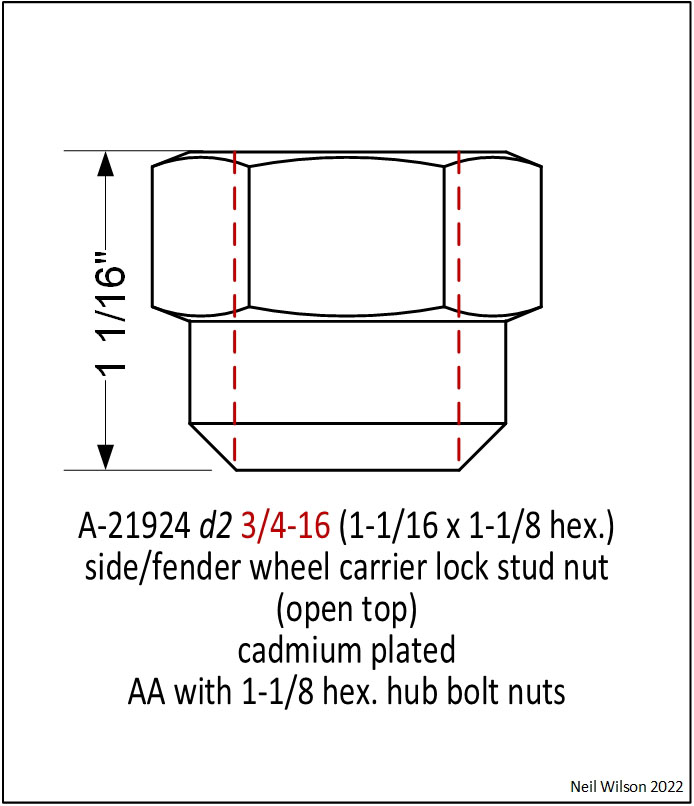

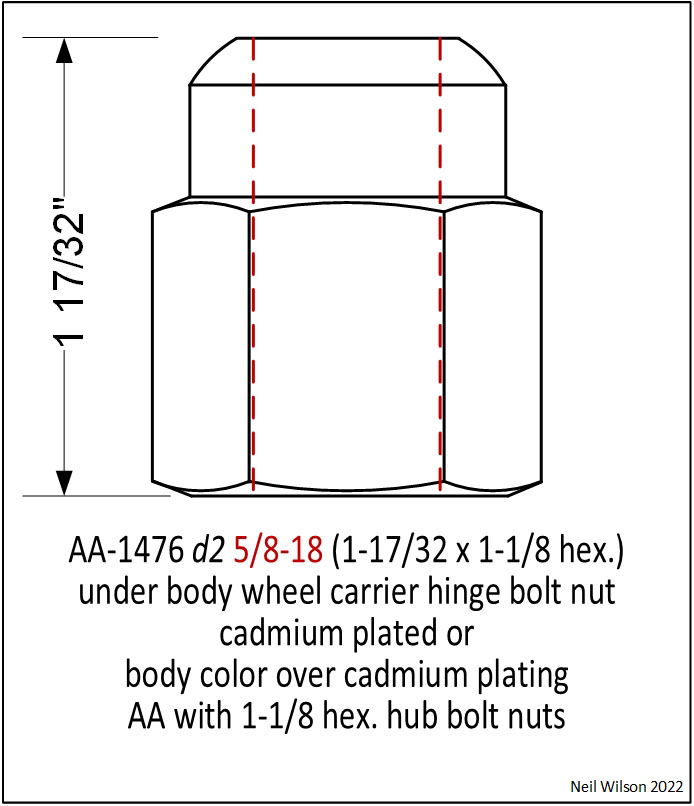

Note that the red dashed vertical lines represent the nut inside threads

The first five nuts below were replaced for many AA-trucks in 1929 (see Wheel & Carrier Nut Replacement).

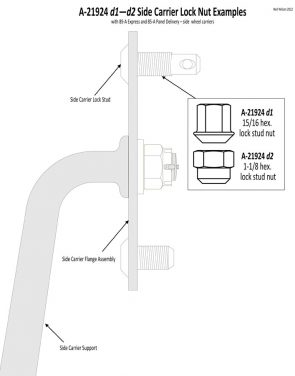

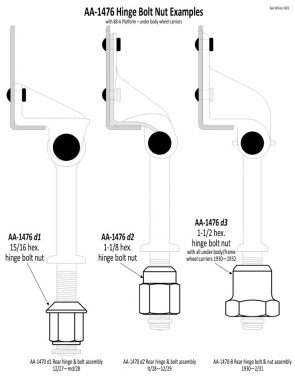

Wheel Carrier Lock Stud & Hinge Bold Nuts Examples

Wheel & Carrier Nuts Replacement

In 1929, Ford carried out an AA-spindle replacement for AA-trucks previously assembled with A-chassis spindles (1927—mid-February 1929). For details, see Spindle Recall. This recall was free to the customer. It is likely that most AA-trucks were converted.

For assembly line type restorations, this spindle recall would need to be reversed for originally.

As part of the spindle recall, original wheel and carrier nuts were replaced with the newer 1929, 1-1/8″ hex., nut designs. The two replacements were:

1 – 1927—mid-February 1929 AA-trucks had the front wheel nuts replaced with AA-1120/21 RH/LH wheel nuts.

2 – AA-trucks with original 15/16 hex. nuts had the following new parts replacing original parts:

- AA-1120 RH hub bolt nuts for both rear hubs

- AA-1120 RH hub bolt nuts for wheel carrier

- A-21924 d2 side wheel carrier lock nut

- AA-1476 d2 under body wheel carrier hinge bolt nut

- AA-17036-B starting crank and wheel nut wrench (used for 1-1/8″ hex. wheel nuts) – replaced AA-17036 wrench used for 15/16 hex. wheel nuts.

Hub/Drum Assemblies

Documentation to be added. Refer to RGJS page E-46.

Hub Caps

Section Contents – Hub Caps

Overview

This article covers the five AA hub caps used during the 1927—1932 AA-chassis production.

Refer to the RGJS E Supplement Area E22 for a condensed version of the information in this hub caps article.

This article uses the name “hub cap” except when listing a part name from Ford engineering part drawings/releases or from a Ford Parts-Price-List. The following various names were used by Ford:

- AA-1130 d1-d5 (with AA-1015 steel spoke wheel) – on drawing: wheel shell cap; on release record: wire wheel hub shell cap; on Parts-Price-List: wheel hub shell cap

- AA-1130-B (with AA-1015-B disc wheel) – disc wheel hub cap

- AA-1130-C (with AA-1015-C disc wheel and with AA-1015-F 18″ disc wheel) – hub cap – rear or rear hub cap

- AA-1131 (with AA-1015-C disc wheel) – hub cap – front or front hub cap

- AA-1137 (with AA-1015-E steel spoke wheel) – on drawing: wire wheel hub cap assembly; on Parts-Price-List: hub cap

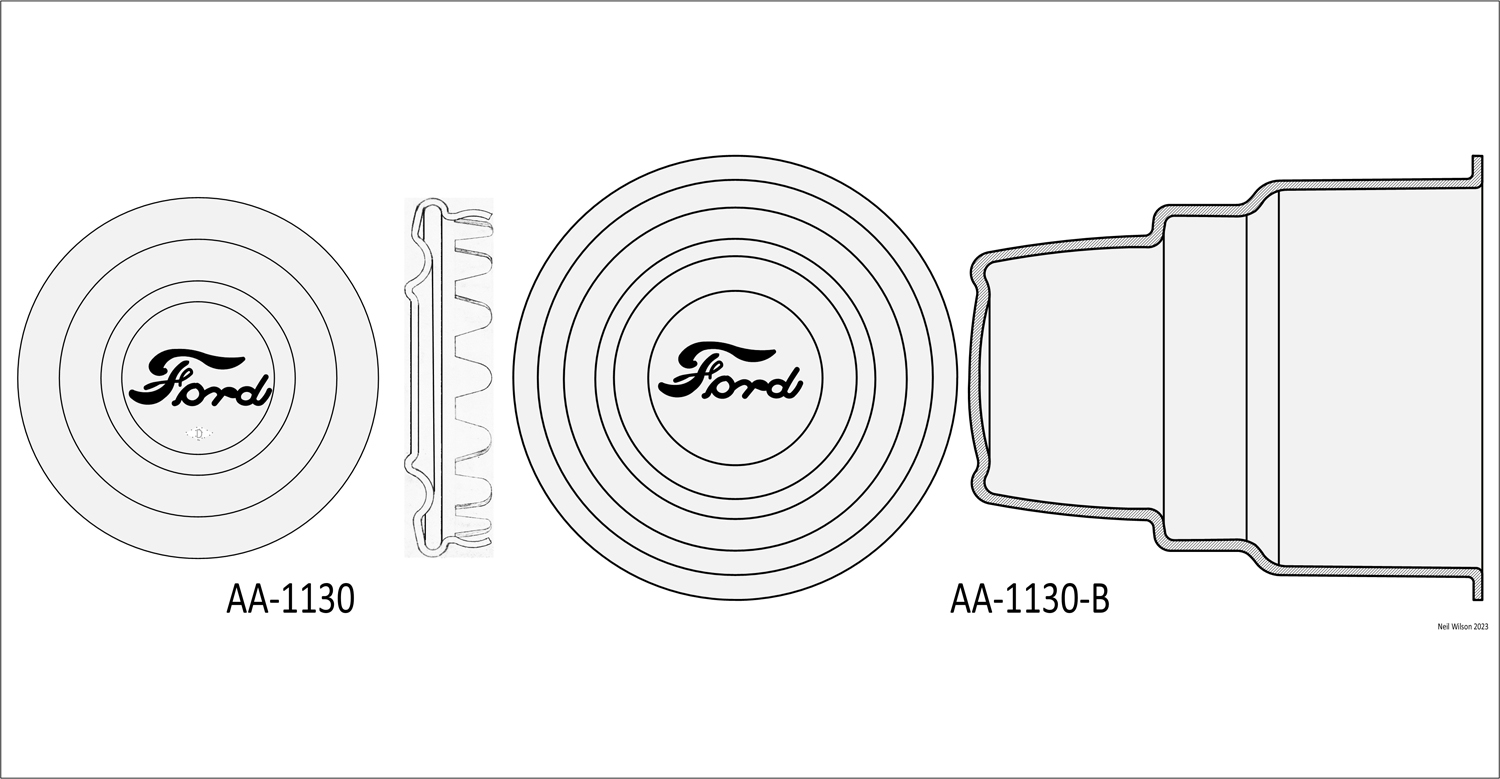

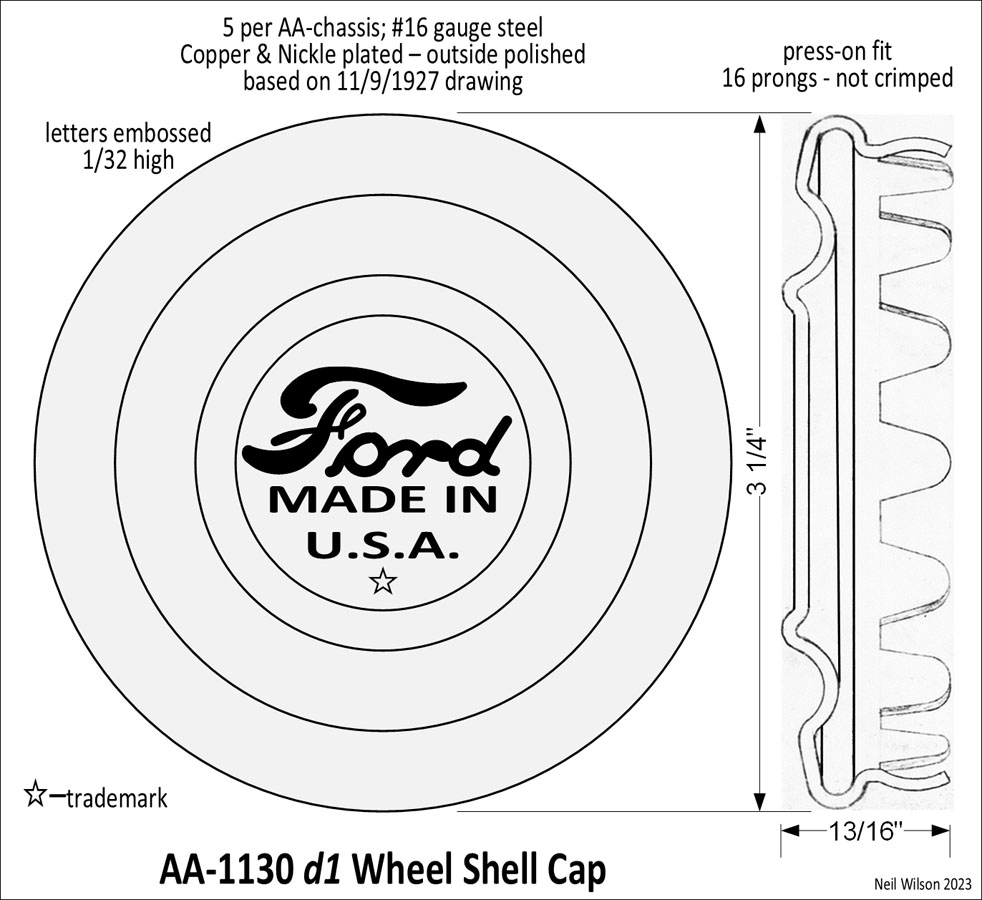

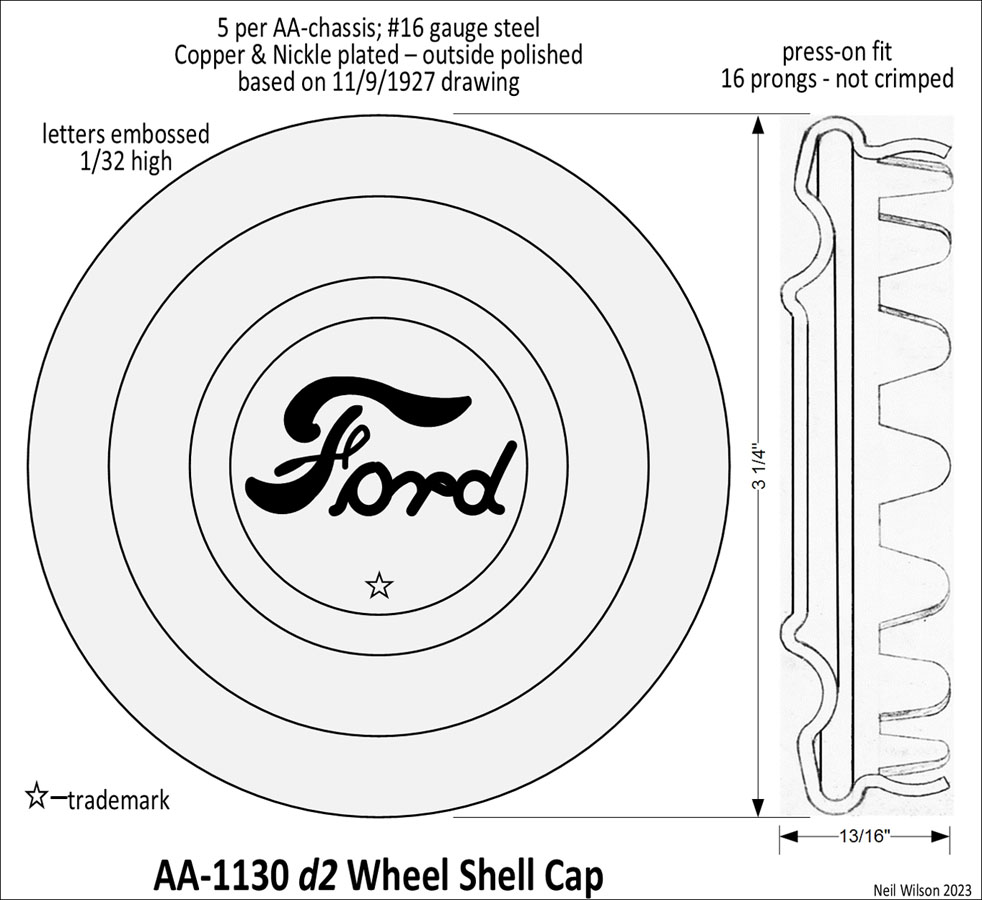

AA-1130 d1—d5 Hub Cap

AA-1130 d1 Hub Cap

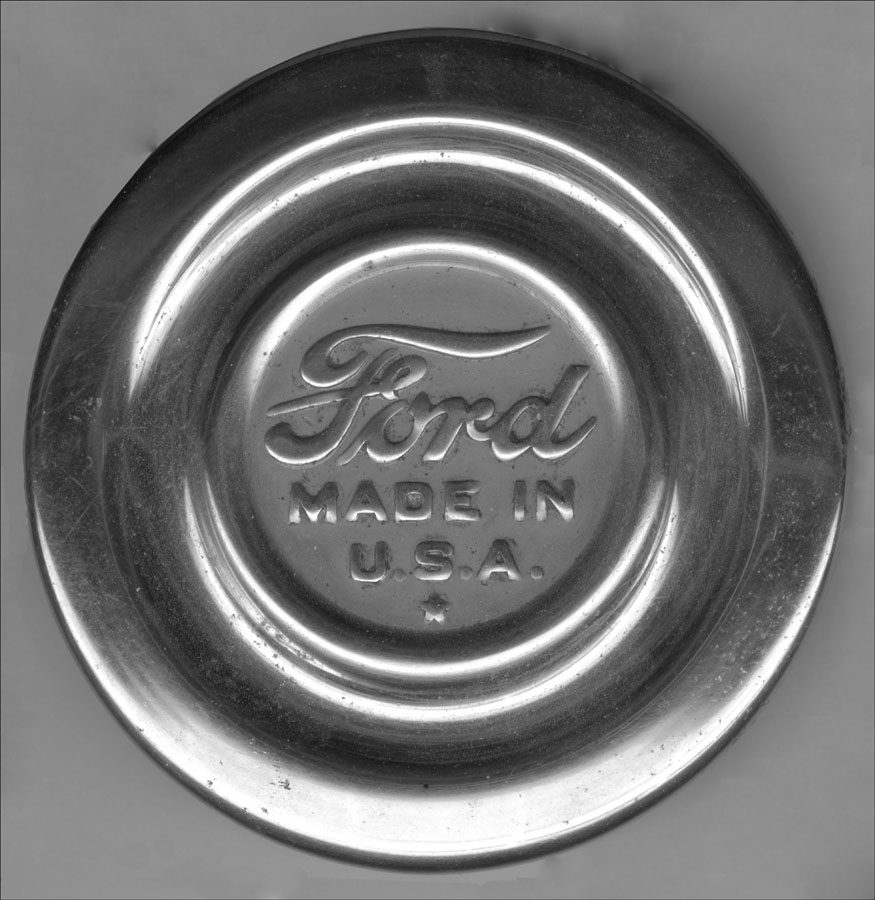

The first AA-chassis hub cap was named “Wheel Shell Cap”. There were five require per AA-chassis. It was used from 12/27—2/28. Refer to the drawing and photograph following showing this first design.

The hub cap was made of #16 U.S. gauge steel as per the 11/9/27 Ford drawing used for AA-1130 reference.

The lettering “Ford MADE IN U.S.A.” was embossed 1/32″ high.

The ☆ was not specified on the Ford drawing. It was a manufacture’s trademark (that is currently unidentified). All hub caps observed have the ☆ trademark.

The hub cap finish was specified as “Copper & Nickel Plate, Polish Outside”. There was a note (not yet found) specifying that the background for the letters was to be a dull finish.

There were sixteen prongs that held the hub cap to the wheel (a press-on fit). If prongs are crimped to hold the hub cap to the wheel, they will break off. This is unlike A-chassis hub caps.

The Ford drawing noted – “Was – TTX-6803-B”. Identification of this hub cap has not been found.

For restoration – prior to plating, the prongs should be adjusted to insure a tight press-on fit to the wheel.

Suggestion – use caulking at 3—4 prongs after installation of hub cap. This provides better security against loss. These hub caps are too rare/expensive to replace.

AA-1130 d2 Hub Cap

On 3/1/28, design 2 of hub cap AA-1130 was introduced. It was the same as design 1 but the lettering “MADE IN U.S.A.” was eliminated and the Ford script was relocated in the centered of the field area of the cap.

Although moved slightly up, the ☆ manufacture’s trademark continued to be embossed below the Ford script. No other trademark has been found (to date).

The Ford script was a fair amount taller than the d1 Ford lettering as can be seen in the following photograph.

The finish of the hub cap was changed to – “Polish Outside, Cooper Plate, Buff, Nickel Plate, Buff”.

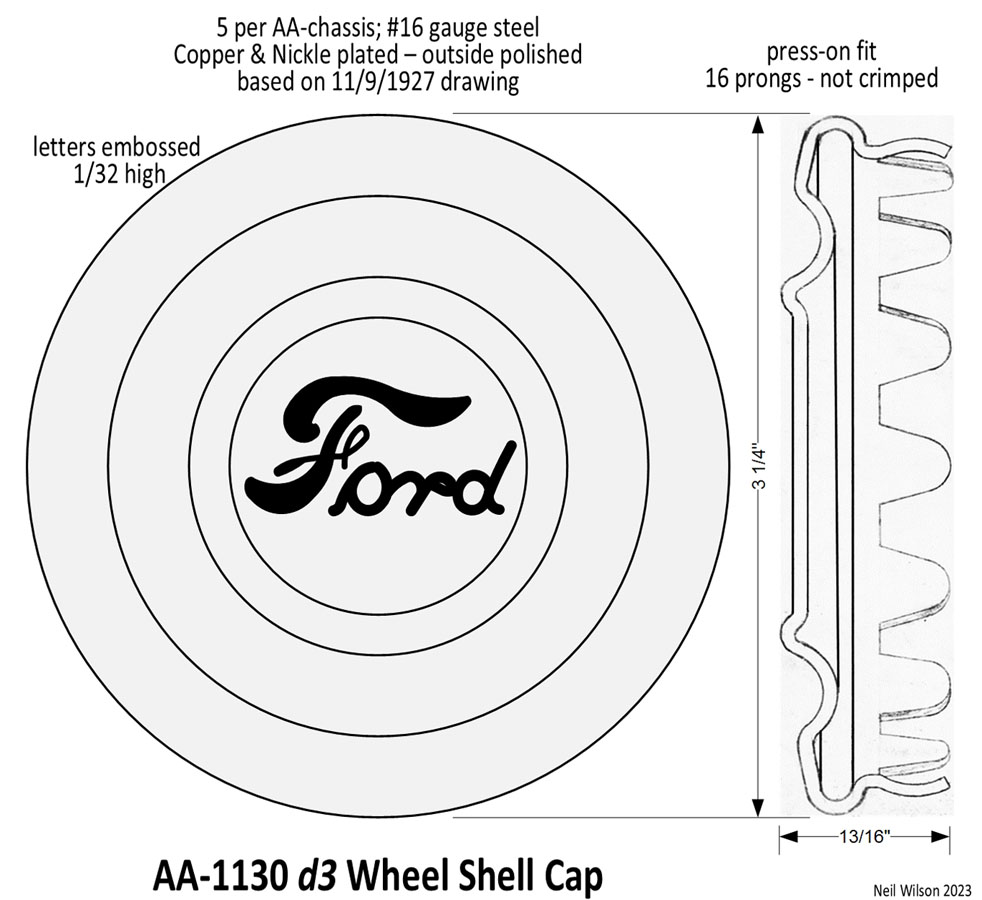

AA-1130 d3 Hub Cap

On 5/28/28 the Ford release record specifies that the manufacture’s identification mark (i.e. trademark) was to be stamped on the inside instead of the outside.

Examples for d3 show the same taller Ford script as found on the d2 hub cap. In addition, there was no trademark stamped on the inside.

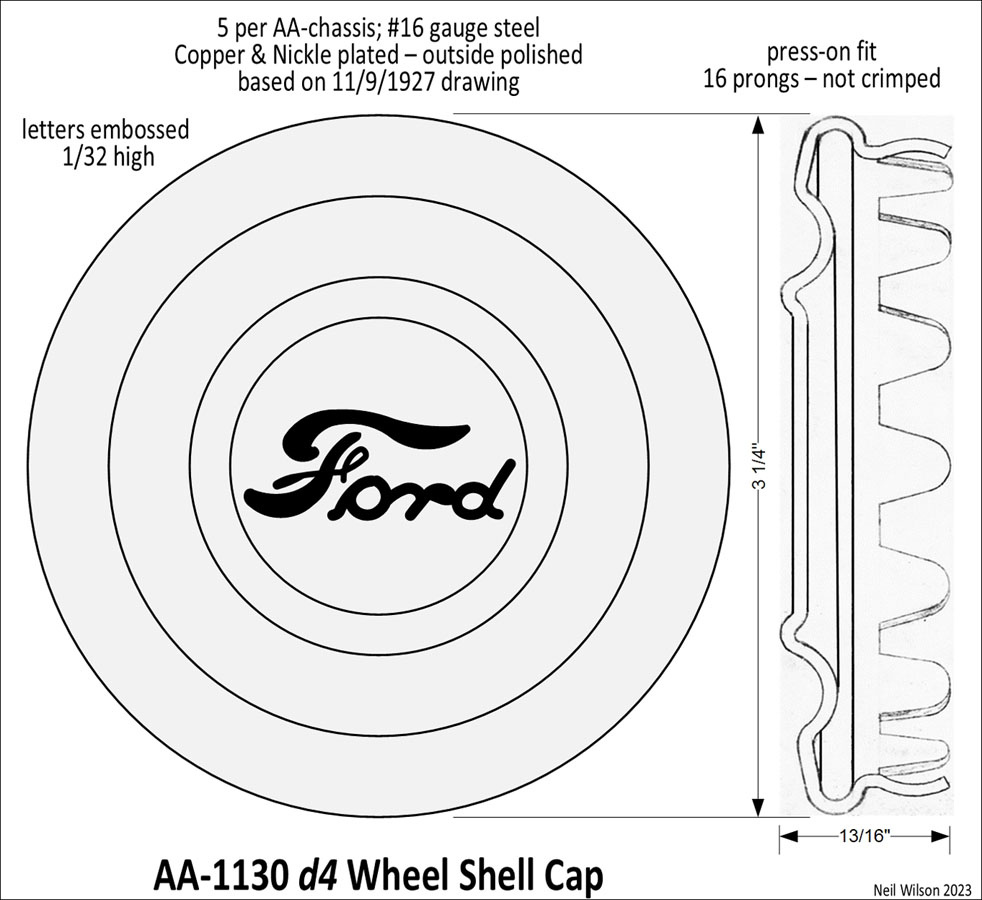

AA-1130 d4 Hub Cap

The d4 AA-1130 hub cap started production at some date after 5/28/28. For this design, the Ford script was shorter. This was closer to the 11/9/27 Ford drawing script size.

There was no manufacture’s trademark found on the inside of the hub cap.

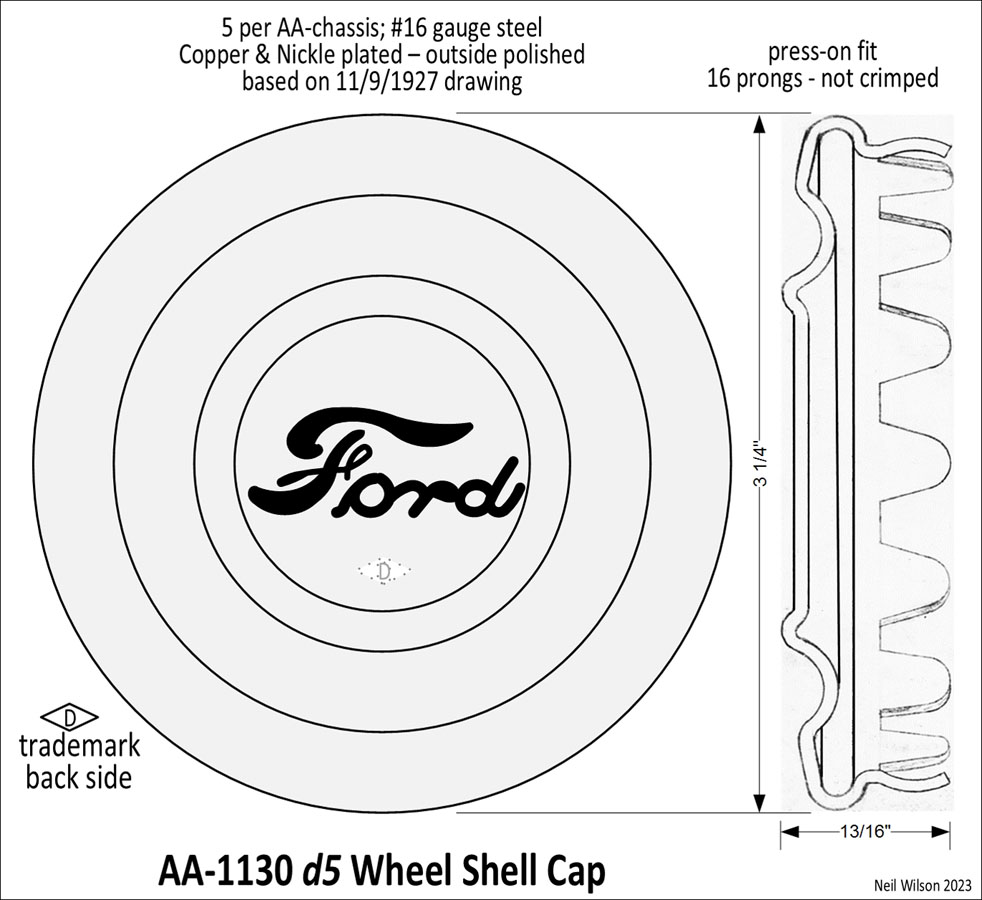

AA-1130 d5 Hub Cap

The d5 AA-1130 hub cap started production at some date after the d4 hub cap. For this design, the Ford script was also short (like the d4 script) but slightly bolder.

A manufacture’s trademark was on the inside as shown in the following images. This hub cap is the design frequently found is today’s market.

Ford release records show that on 7/23/28 a note was removed which had specified that the background for letters to be a dull finish.

Note that prior release records do not indicate that this note was added. The note was not on the 11/9/27 used for reference.

On 9/28/28, an “A” suffix was added to the part id. This was the date of the initial Ford drawing for the replacement AA-1130-B Disk Wheel Hub Cap was produced.

On 3/22/29, the suffix was changed from “A” to “AR”, indicating the hub cap was to be used for repairs only (i.e. no longer an assembly line production part).

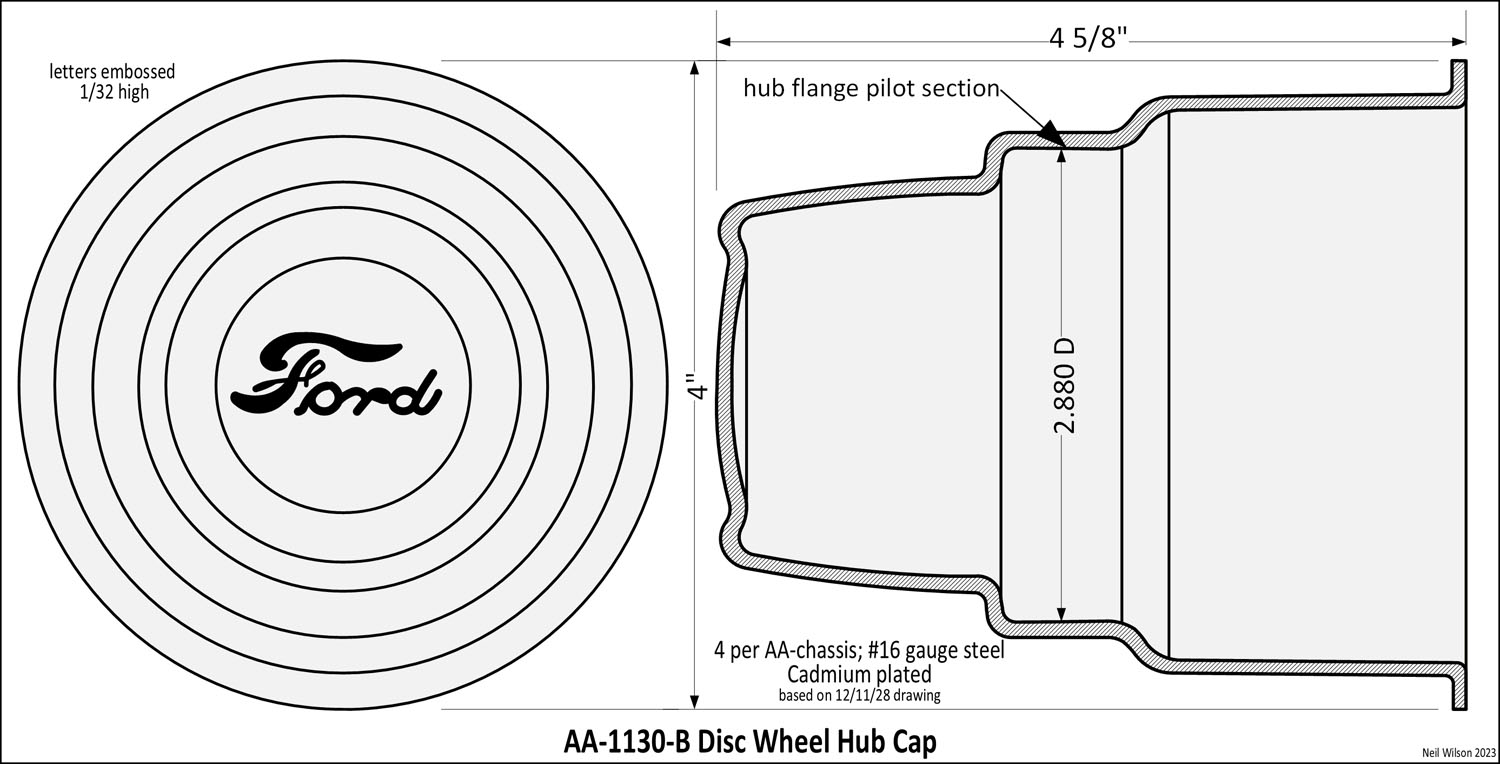

AA-1130-B Disc Wheel Hub Cap

The Ford release records and the 12/11/28 Ford engineering drawing were used as research for this AA-1130-B hub cap. This was the last drawing prior to production (no additional drawings are listed during the 2/29—12/29 production time frame).

With the introduction of the AA-1015-B disc wheel in February 1929, the AA-1130-B hub cap was released for assembly line use.

The hub cap was #16 U.S. gauge steel and had a cadmium plated finish. The “Ford” lettering was embossed 1/32″ high.

A drawing and photograph of this hub cap is shown below. It was a 4″ diameter, 3-tiered design with a length of 4-5/8″. It fit over the AA-chassis hubs.

The second tier (also referenced as the hub flange pilot section) of hub cap AA-1130-B fit closely over the hub flange.

Prior to production, there were three 1928 minor changes to the diameter of this pilot section diameter.

The AA-1015-B disc wheel had a flat surface which mated with the hub cap flange and held it firmly in place once the wheel was installed.

There were four of these hub caps per AA-chassis. They were used for the ground wheels. There was no hub cap used with the wheel carrier.

For the 85-A Panel Delivery and 89-A Express bodied AA-trucks, the Side Wheel Carrier Installation #4 was used with this disc wheel. Rather than using a hub cap, this carrier included an AA-1423 carrier support nut cover to protect from wheel theft. This cover also gave a finished look to the installation.

The 88-A platform bodied AA-trucks continued to use the Under Body Wheel Carrier Installation #2.

In 8/9/29, an “R” was added to the part id suffix. This identified part AA-1130-BR as a repair part. However, this hub cap was used in production through December 1929.

The Ford release records shows that this hub cap was also used for the AAF-chassis with dual wheels. Anyone know anything about this (contact Neil Wilson please).

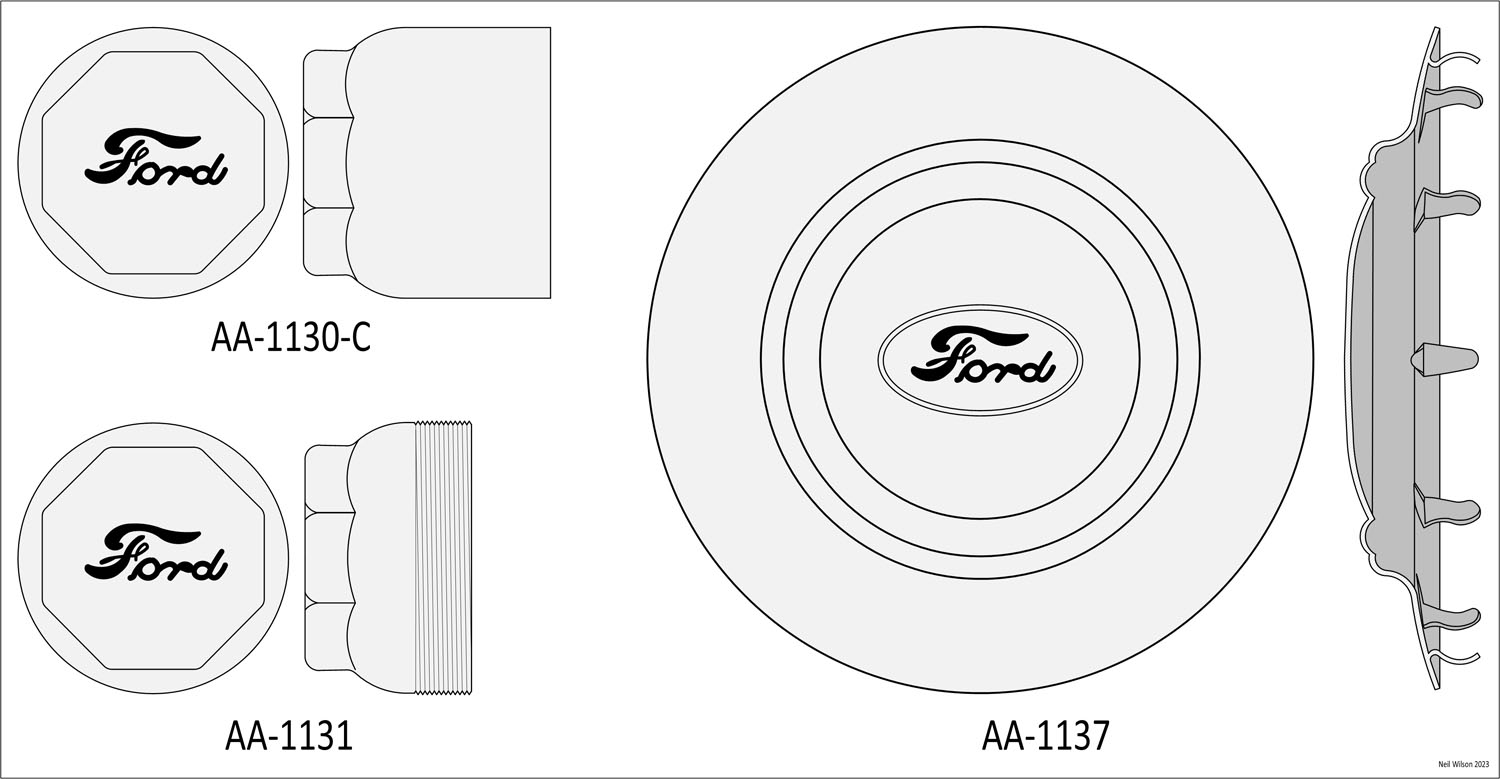

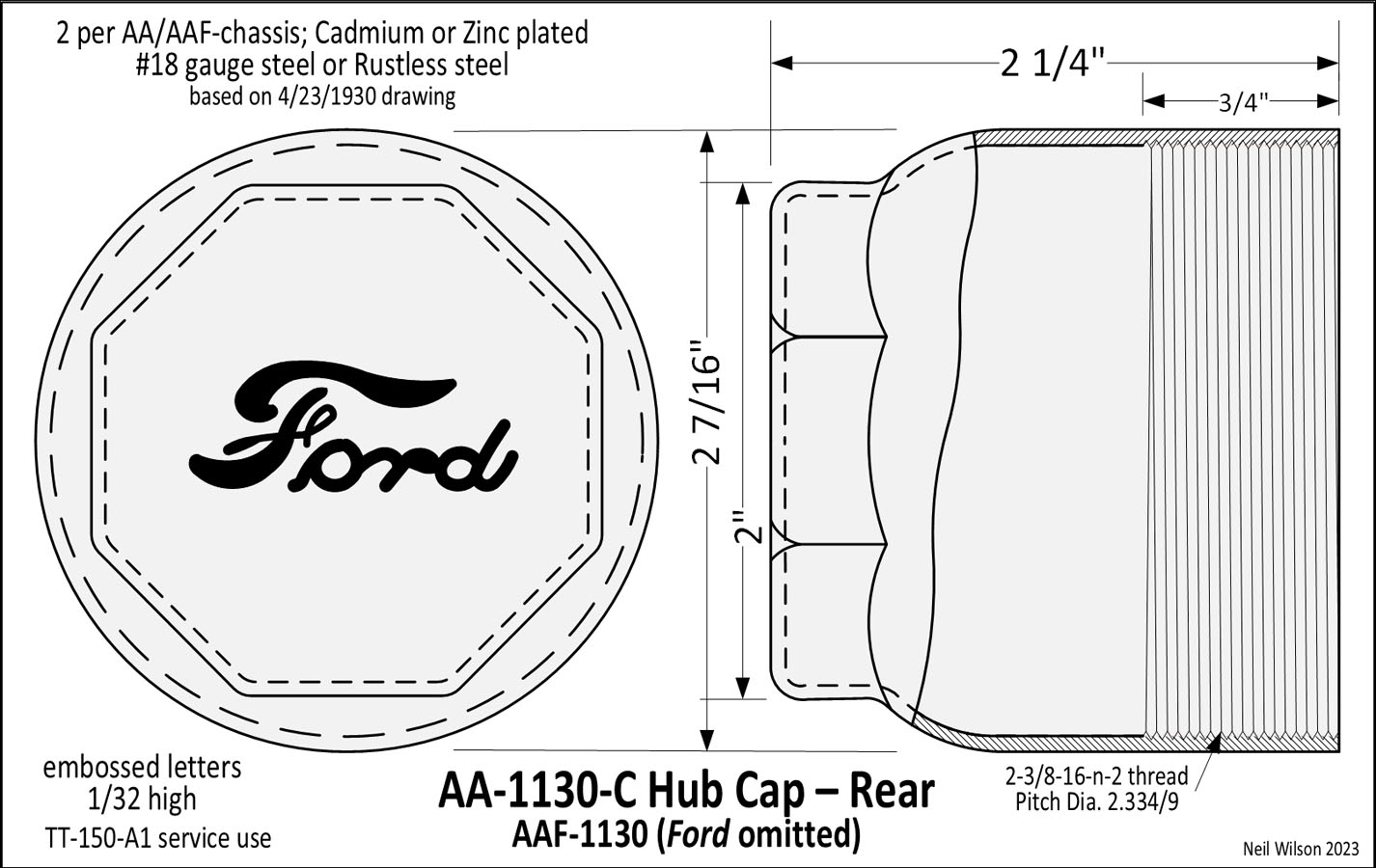

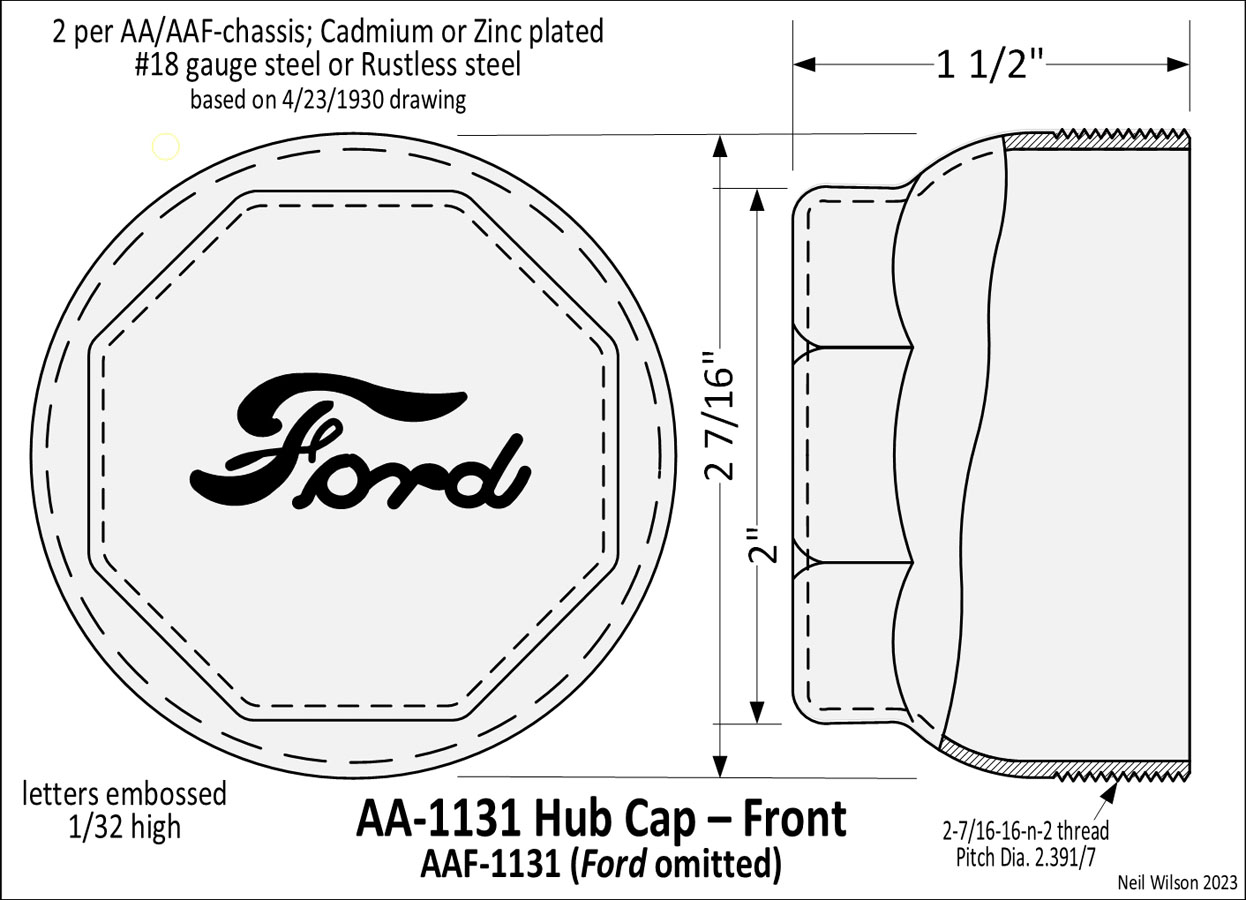

AA-1130-C Rear & AA-1131 Front Hub Caps

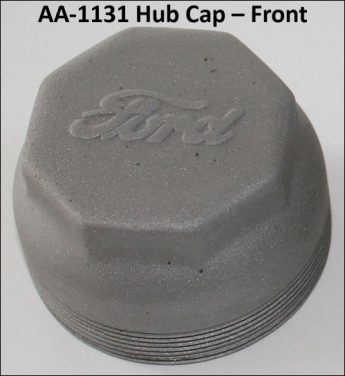

Ford engineering drawings dated 4/23/1930 were used as research for these AA-1130-C rear and AA-1131 front hub caps. The drawings and photos below provides visuals of these hub caps.

Starting January 1930, new front and rear ends along with a new heavier frame front cross member were placed into production. The new front/rear hubs were designed to accept screw-on type hub caps.

The AA-chassis rear hub caps were part AA-1130-C. This hub cap had a diameter of 2-7/16″ and was 2-1/4″ long. The AA-chassis front hub caps were part AA-1131. This hub cap had the same 2-7/16″ diameter with a length of 1-1/2″.

The AA-1130-C rear hub cap had 2-3/8-16-N-2 internal threads. The threads extended 11/16″—3/4″ from the inside end of the hub cap. It screwed onto the corresponding externally threaded rear hub.

The AA-1131 front hub cap had 2-7/16-16-N-2 external threads. The threads extended 7/16″—1/2″ from the inside end of the hub cap. It screwed into the corresponding internally threaded front hub.

The outside end of each hub cap was an octagon that was 2″ across the flats and 3/8″ tall.

The Ford lettering was embossed 1/32″ high. Two of each hub cap was required per AA-chassis.

These hub caps were made of #18 U.S. gauge steel or rustless steel. The finish was Cadmium or Zinc plating. This plating applied to both the steel and rustless steel hub caps. Note that this is based on the absence of any special finish requirements for the rustless steel hub caps on the Ford drawings.

These same hub caps (less the Ford name) were parts AAF-1130 and AAF-1131 for the Canadian AA-chassis. Two of each hub cap were required per AAF-chassis.

For the 2″ octagon wrench size end of these hub caps, an “AA Truck Hub Cap Wrench” was been found on 2/23/23. An oversized 12-point socket can be used for removal/installation of these hub caps. The original multi-wrench-sized Model T tool will not work since it has a 1-5/8″ octagon wrench.

On the Ford drawing, AA-1130-C rear hub cap was specified for servicing part TT-150-A1 (i.e. a factory part number). This was service part TT-1116 Rear Hub Cap.

Note: For the 1927 Ford Parts-Price-List (and prior dates) there are “Model” and “Factory Number” columns. And, the “Part Number” column contains the plain service part number + any part suffix. Consequently, part# 1116 was a rear hub cap with TT in the “Model” column and 150 in the “Factory Number” column.

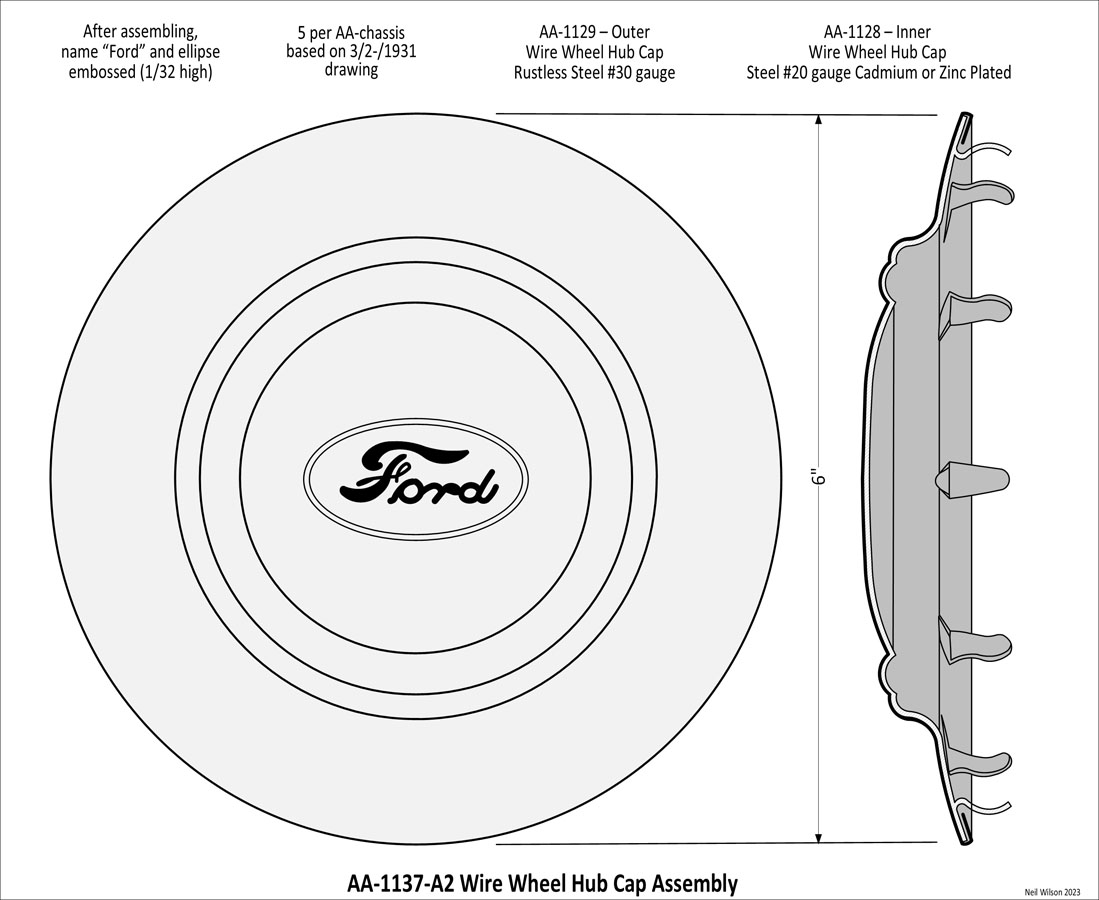

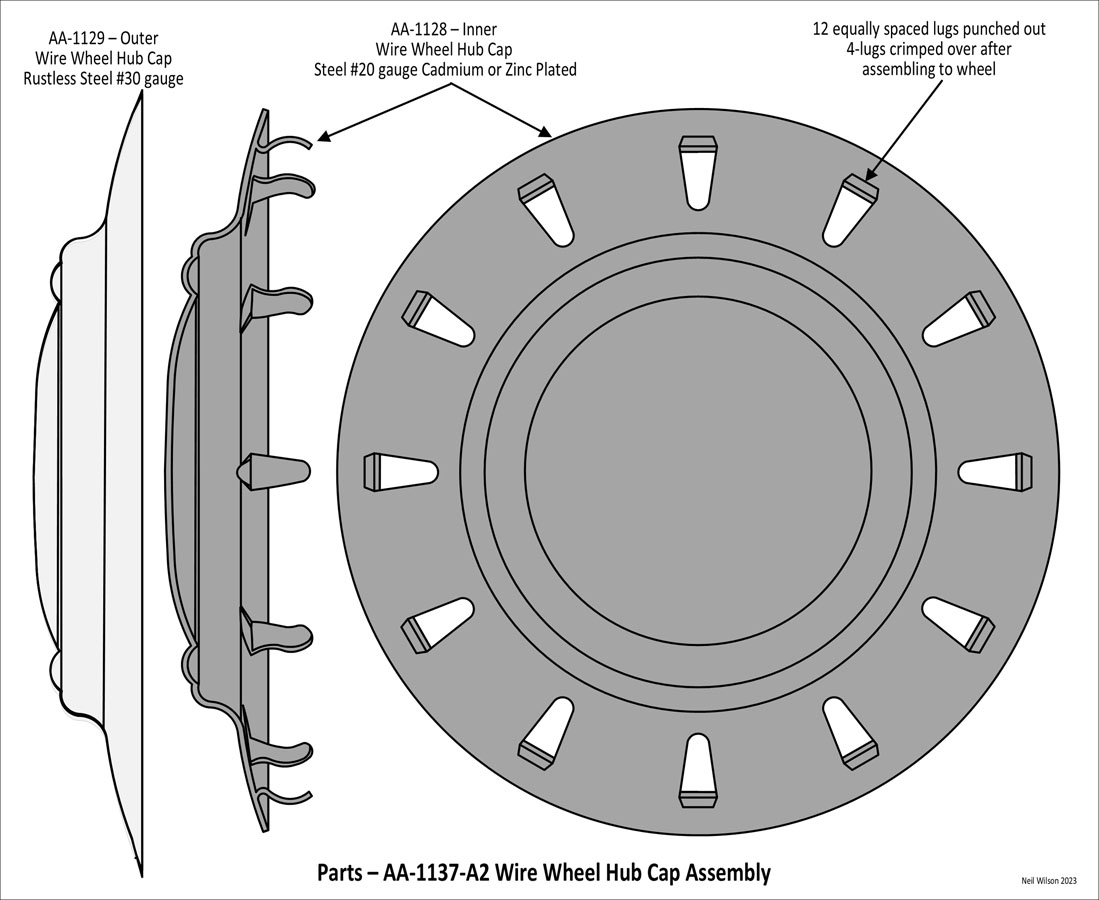

AA-1137 Wire Wheel Hub Cap Assembly

On the Ford Parts-Price-List, this hub cap is listed as – “AA-1137 hub cap — with AA-1015-E”. The diameter and height were specified as – “To be determined from shop practice”. It was approximately 6″ in diameter.

It was an assembly of AA-1128 inner and AA-1129 outer parts. The inner part was cadmium or zinc plated. The outer part was rustless steel with the outer surface polished a bright finish.

The 3/20/31 Ford engineering drawing specifies – “After assembling, emboss name “Ford” in script. Lettering and ellipse 1/32 high.” Consequently, the Ford script and ellipse can be seen on the inside of the assembly.

Note that AA-1015-E was a 20” steel spoke wheel used as optional equipment for Briggs-closed-body-types (270-A, 275-A, 280-A, 285-A, 290-A, and 300-A). Production for these types was 2/31—3/32.

The wheel had a larger bolt pattern and required special hubs and drums.

These wheels may have been made standard equipment for some of these body types at some time in 1931.

The inner part had 12 stamper lugs with a diameter of 5.510/5.520. The 3/20/31 Ford engineering drawing specifies – “4-lugs to be crimped over after assembling to wheel.”

Tires

Not sold by Ford (not a Ford chassis part). Documentation to be added. Refer to RGJS page E-97.

Link to AA Truck Talk – Tire Installation .pdf document:

Tire Installation Document (.pdf file)

Tire Valve Hardware

Not sold by Ford (not a Ford chassis part). Documentation to be added. Refer to RGJS page E-100.