2023/11/30 update

Page Contents

AA Vehicle Windshield Assemblies – Overview

There were six different windshield assemblies use during AA’s production. Two for the open cabs and five for closed cabs and AA closed body types.

Open Cab

Windshield assembly A-37105 was used through June 1930 for the 76-A open cab. This same assembly was used for the 35-A phaeton and 40-A roadster through 1929. In June 1930 the 76-B open cab was introduced. It used windshield assembly A-77405.

Note that the 76-A and 76-B were used on both the A and AA chassis.

Closed Bodies

Windshield assembly A-79405 was used through June 1930 for the 79-A Panel Delivery, 82-A Closed Cab and 85-A Panel Delivery. This assembly had seven designs. When new body types 79-B Panel Delivery, 82-B Closed Cab and 85-B Panel Delivery were introduced in June 1930, a new A-45405-E windshield assembly was used. The A-45405-E assembly was also use on AA closed body types introduced in early 1931. The 315-A Standrive and 330-A/B school/passenger bus used their own AA unique windshields assemblies.

Note that the 79-A Panel Delivery was an A chassis body type only. The 82-A Closed Cab was used on both the A and AA chassis.

The table below is by AA body type. For each body, links are provided to details for the windshield assembly and corresponding windshield female hinge.

| Ford Model AA’s – Windshield Assemblies Table | |||

|---|---|---|---|

| Type | Body Name | Windshield | |

| Assembly | Hinge (female) | ||

| Neil Wilson 2018 | |||

| 75-A | Chassis Seat | none | none |

| 76-A | Open Cab | A 37105 | none |

| 76-B | Open Cab | A 77405 | none |

| 82-A | Closed Cab | A 79405 d1-d7 | A 79510 d1-d2 |

| 82-B | Closed Cab | A 45405-E | A 45510-C |

| 85-A | Panel Delivery | A 79405 d1-d7 | A 79510 d1-d2 |

| 85-B | Panel Delivery | A 45405-E | A 45510-C |

| 210-A | Panel Delivery | A 45405-E | A 45510-C |

| 270-A | Funeral Service | A 45405-E | A 45510-C |

| 275-A | Funeral Coach | A 45405-E | A 45510-C |

| 280-A | Ambulance | A 45405-E | A 45510-C |

| 285-A | DeLuxe Police Patrol | A 45405-E | A 45510-C |

| 290-A | Standard Police Patrol | A 45405-E | A 45510-C |

| 300-A | DeLuxe Delivery | A 45405-E | A 45510-C |

| 315-A | Standrive | AA 315405…upper | AA 315510 |

| AA 315406…lower | none | ||

| 330-A | School Bus | AA 330405 | unknown |

| 330-B | Passenger Bus | AA 330405 | unknown |

| AAAAA | |||

The following information is sequenced by windshield assembly part-id. Refer to the Windshield Assemblies Table above for links to the windshield assembly used by body type.

Windshield Assembly A-37105

76-A open cab ???????????????. Under construction

Windshield Assembly A-45405-E and Female Hinge A-45510-C

This windshield assembly was used with the 82-B Closed Cab, 85-B Panel Delivery, and closed AA body types which started production in early 1931 (except the 315-A Standrive, 330-A School Bus, and 330-B Passenger Bus) – Refer to the Windshield Assemblies Table above to determine body type which used this assembly.

Under construction

Windshield Frame Assembly – A-45410

Windshield Glass Assembly – A-45455-B

Windshield Hinge (Female) – A-45510-C

Swing-Arm A-45463-B (used with windshield assembly A-45405-E)

Windshield Parts List – A-45405-E

Windshield Assembly A-77405

76-B open cab ???????????????. Under Construction

Windshield Assembly A-79405 d1-d7 and Female Hinge A-79510 d1-d2

This windshield assembly was used with the 82-A Closed Cab and panel deliveries which were in production into June of 1930. An example is shown to the right. Parts which were unique to this assembly were:

- Windshield assembly (frame, glass, and weather strips) – A-79405

- Female windshield hinge – A-79510

- Swing-arm spacer – A-79490

- Swing-arm bushing nuts – A-79???

Note that these unique parts were assigned part ids for the 79-A Panel Delivery (an A chassis body). Both the 82-A Closed Cab and 85-A Panel Delivery shared these parts. These three body types used a unique hand operated wiper (not covered in this article).

The panel deliveries did not actually appear in production until August 1928. They were therefore fit with windshield part designs being used for the 82-A Closed Cab as of August 1928.

This windshield assembly had seven designs and the corresponding female hinge had two designs. Design one of both parts were only used for a short time into early 1928. These first designs were obsoleted and were not available through Ford service. The design two parts continued with the same part ids. Each subsequent design replaced the prior design without part id changes. Therefore, all designs were backwards compatible.

The windshield frame assembly and female hinge were hung on the paint assembly line and painted body color (including the upper to lower frame fasteners). The windshield glass and weather strips were installed after painting.

Windshield Frame Assembly A-79410

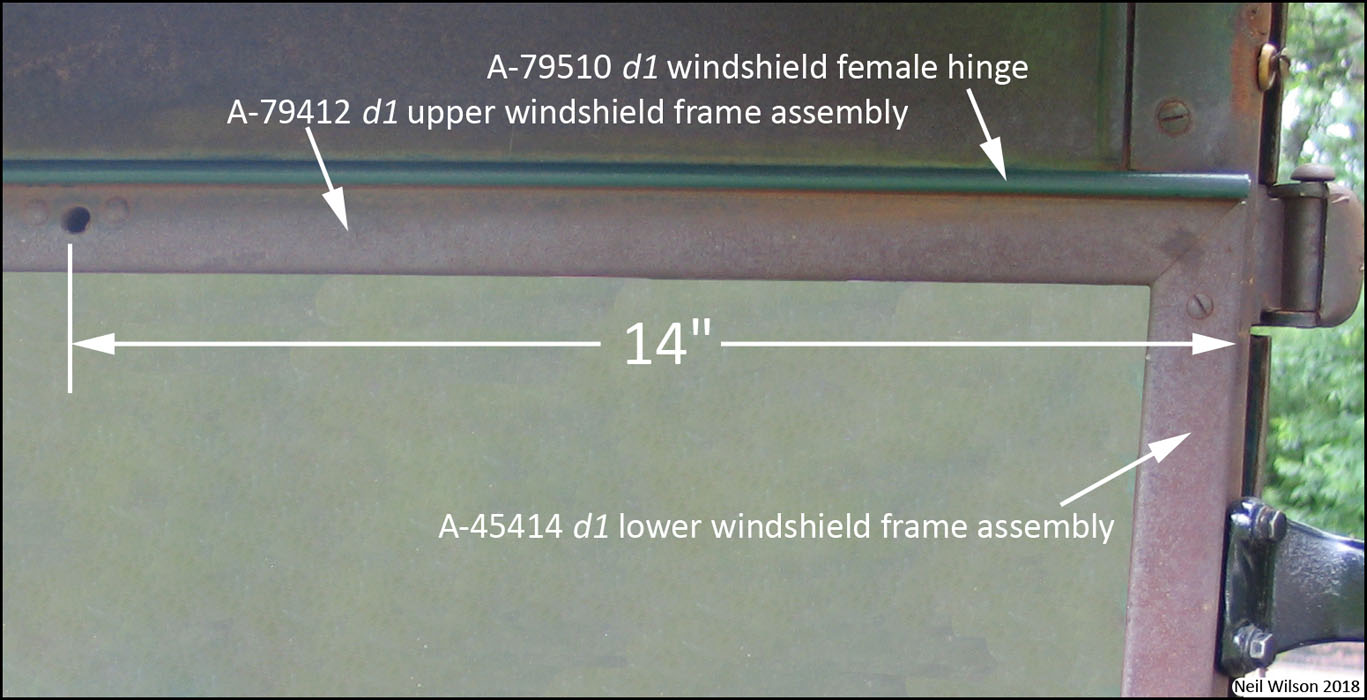

The windshield frame assembly A-79410 included upper and lower assemblies. The upper assembly carried 79-A Panel Delivery part A-79412 and was shared by the 82-A Closed Cab and 85-A Panel Delivery. The lower assembly carried Coupe part A-45414 and was shared by many passenger car and light commercial vehicles.

Upper Windshield Frame Assembly A-79412 d1-d2

see gallery

Design 1 – The installation hole for the hand wiper was 14″ from the left edge of the frame. A d1 windshield hinge as well as a d1 header upholstery panel was required. This d1 parts combination was used at least into February 1928 since it has been found on an early February 1928 82-A close cab truck.Design 2 – The installation hole for the hand wiper was 12-3/4″ from the left edge of the frame. Production start for d2 was early 1928. It required a d2 hinge and d2 header upholstery panel.

Note that d1 and d2 parts were not interchangeable. A change to any of d1 parts required changing all three parts to d2 parts. The d1 parts were not offered through service.

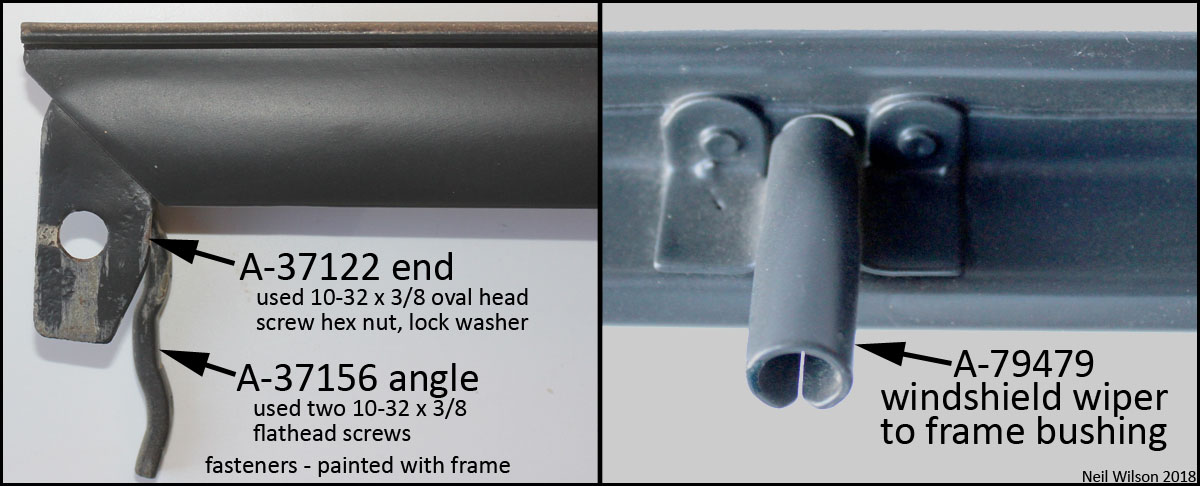

Upper Windshield Frame Assembly Sub-Parts

see gallery

Parts A-37112 ends and A-37156 angles were hidden when fit into the lower frame. The oval head screw showed on the face of the frame. The flathead screws were visible on the side of the frame. These fasteners were painted body color. A-79479 wiper bushing extended into the cab through a cutout in the female hinge.

- A-79412 d1 Upper Windshield Frame Assembly

- A-79412 d2 Upper Windshield Frame Assembly

- Upper Windshield Frame Assembly Sub-Parts

Lower Windshield Frame Assembly A-45414 d1-d7

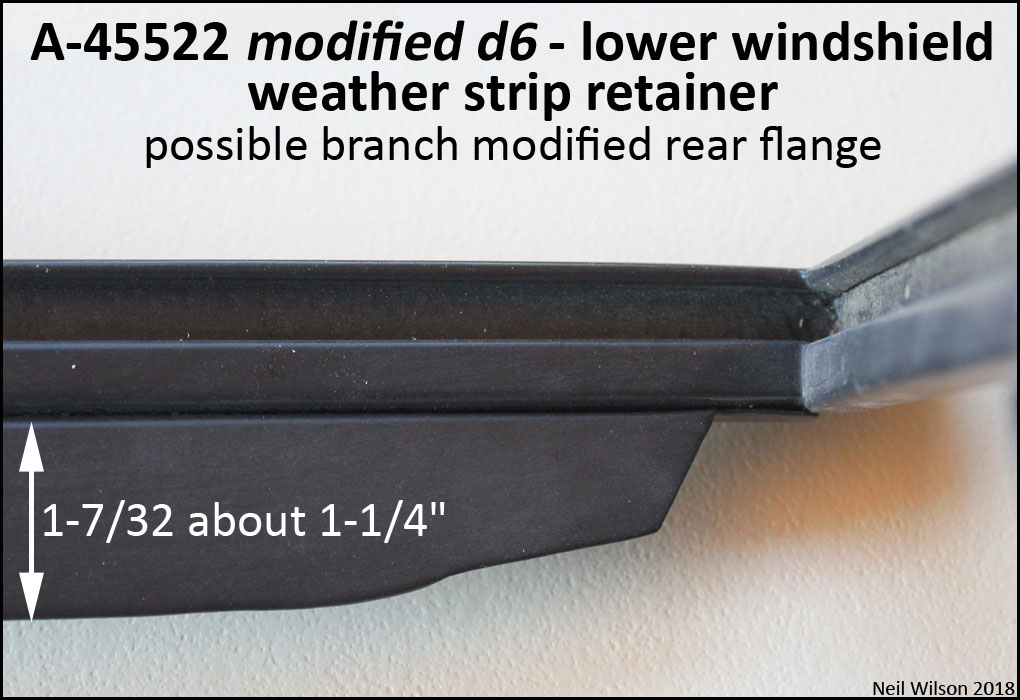

This lower frame assembly had seven designs as shown in the gallery below. These different designs were because of changes to the lower windshield weather strip retainer A-45522. This retainer held the lower rubber weather strip. The weather strip, along with the two side weather strips, sealed the windshield when closed.

The rear flange of retainer A-45522 was designed to act as a wind deflector when the windshield was opened with the swing-arms. The flange was folded under itself for strength.

The flange designs were backwards compatible. Consequently there was no change to part ids. A service replacement lower frame could be installed on a vehicle which originally had a prior design.

The 79-A Panel Delivery, 82-A Closed Cab, and 85-A Panel Delivery continued in production into June 1930. These body types continued using the A-45414 lower windshield frame assembly with the d7 retainer design and the A-45437 swing-arm frame brackets.

- A-45522 d1 Lower Windshield Weather Strip Retainer

- A-45522 d2-d3 Lower Windshield Weather Strip Retainer

- A-45522 d4-d6 Lower Windshield Weather Strip Retainer

- A-45522 d7 Lower Windshield Weather Strip Retainer

Dates when these lower windshield weather strip retainer designs were likely used are as follows:

d1 – start-er/28 with 1″ width, square-clipped ends, 1″ end notches, 90° to glass (thick swing-arms)

d2 – er/28-5/28 with 1″ width, square ends, 1″ end notches, 90° to glass (thick swing-arms)

d3 – 5/28-12/28 with 1″ width, square ends, 1″ end notches, 82° to glass (thick swing-arms)

d4 – 1/29-3/29 with 1-1/4″ width, square ends, 1″ end notches, 82° to glass (thin swing-arms)

d5 – 3/29-5/29 with 1-1/4″ width, square ends, 1-1/8″ end notches, 82° to glass (thin swing-arms)

d6 – 4/29-12/29 with 1-1/4″ width, 30° angled ends, 1-1/8″ end notches, 82° to glass (thin swing-arms)

d7 – 1/30-6/30 with 1-1/4″ width, double angled ends, 1-1/8″ end notches, 82° to glass (thin swing-arms)A couple of odd-ball lower retainer designs have been found. A theory is that some of the Ford branches made changes to their excess stock of d6 windshield lower frame assemblies to fit the new “B” suffixed body types. These modified assemblies were also fit with the new frame swing-arm brackets. Consequently, the branches excess stock could be used.

For the 79-A, 82-A, and 85-A body types, these modified lower frame assemblies continued to use the old frame swing-arm brackets. Examples of the modified retainers found are shown below.

A-45414 Lower Frame Modified Gallery

- A-45522 Modified d6 Lower Windshield Weather Strip Retainer

- A-45522 Modified d6 Lower Windshield Weather Strip Retainer

Changes to the retainer applied to many of the passenger vehicles as well. They also used lower frame assembly A-45414 but in conjunction with upper frame assemblies designed for electric wipers. The last retainer design (d7) was required to allowed the flange to fit the 1930-1931 body types such as the 45-B Coupe. For 1930-1931 bodies, a new lower frame assembly was created with different swing-arm brackets.

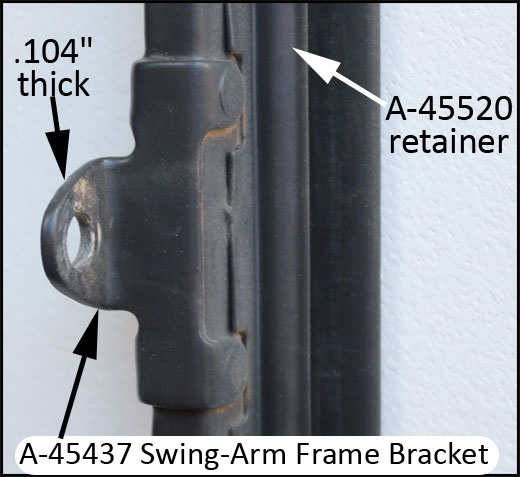

Lower Windshield Frame Assembly – Swing-Arm Frame Bracket A-45437

Each side of the lower windshield frame assembly A-45414 d1-d7 had swing-arm frame bracket A-45437 riveted into place. These brackets were .104″ thick where the bushing nut was inserted for attaching the swing-arm. The right bracket is shown in figure 9. A section of the right windshield weather strip retainer A-45520 can also be seen. It was tack welded in place as part of the assembly.

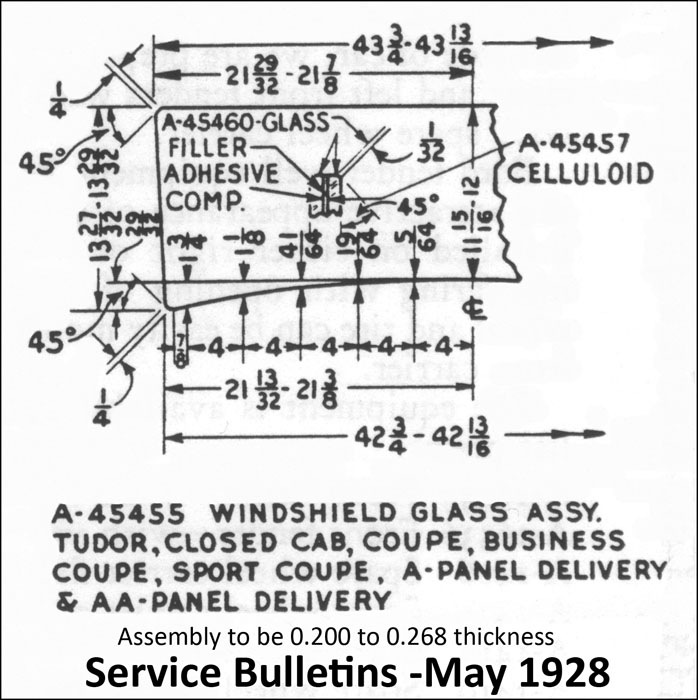

Windshield Glass Assembly A-45455

The windshield glass was an assembly of two layers of A-45460 glass and a layer of A-45457 celluloid in the center. This was “sheet laminated safety glass” as per the RGJS. The detail makeup as found in the May 1928 Ford Service Bulletins is shown below.

The glass was installed with glass retainer strips (i.e. setting tape) which was a canvas backed rubberized cork material.

There was a black edge sealant (tar) which penetrated into the lamination approximately 1/16″ to 1/8″. Starting mid 1929, the sealant was clear.

Windshield Glass Trade Mark

All Ford windshields included a trademark. AA’ers doing assembly-line restorations replicate the trademark based on information in the RGJS. Through 6/30 The 79-A Panel Delivery, 82-A closed cab, and 85-A Panel Delivery had the same trademark as shown in figure 14.

The windshield glass was an assembly of two layers of A-45460 glass and a layer of A-45457 celluloid in the center. This was “sheet laminated safety glass” as per the RGJS. Figure 13 shows the detail makeup as found in the May 1928 Ford Service Bulletins.

The glass was installed with glass retainer strips (i.e. setting tape) which was a canvas backed rubberized cork material.

There was a black edge sealant (tar) which penetrated into the lamination approximately 1/16″ to 1/8″. Starting mid 1929, the sealant was clear.

The trademark was located in the lower right corner of the glass and was readable from the outside. There is an etching kit available to apply the trademark to the glass surface. An Internet search for “Model A Ford Glass Etching Kit” provides the EBay URL.

My understanding is that the original trademark was between the two pieces of glass.

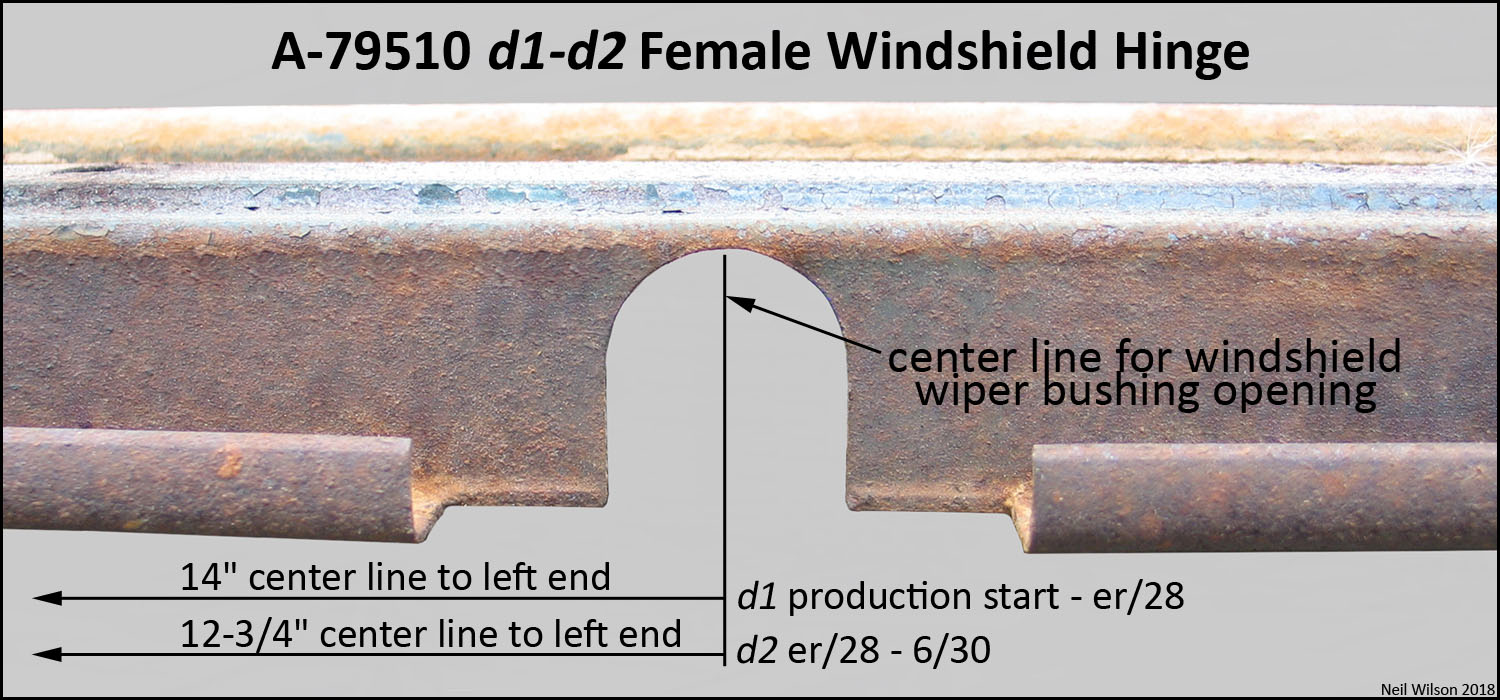

Windshield Hinge (Female) – A-79510 d1-d2

The photograph on the right shows d1 and d2 measurement differences for the two designs of this hinge.

See above gallery for hinge front views.

The hinge was attached to the windshield header panel with five 1/4-20 roundhead, slotted bolts, square nuts, and lock washers. The bolts were inserted through the hinge from the bottom.

There was an anti-rattler (A-45650) used between the header and hinge.

This anti-rattler was a cork or cotton-friction-tape material and could not be seen after hinge installation. Noted from observation, the ends of the female hinge was slightly crimped after windshield assembly installation to keep the windshield centered.

Notes – The windshield should be fit before any finishing to insure it will close properly with the windshield frame rubber seals in place. Cardboard spacers can be used to determine the maximum thickness allowable for the anti-rattler of the hinge. Too much thickness and the windshield will not close properly.

The hinge to header panel should be sealed against water and therefore may require using some paintable caulking on final installation. Page 355 of the Service Bulletins can be referenced for ideas on sealing the hinge. If an incorrect rubber gasket, as sold by vendors, is used, it is likely that the windshield will not fit.

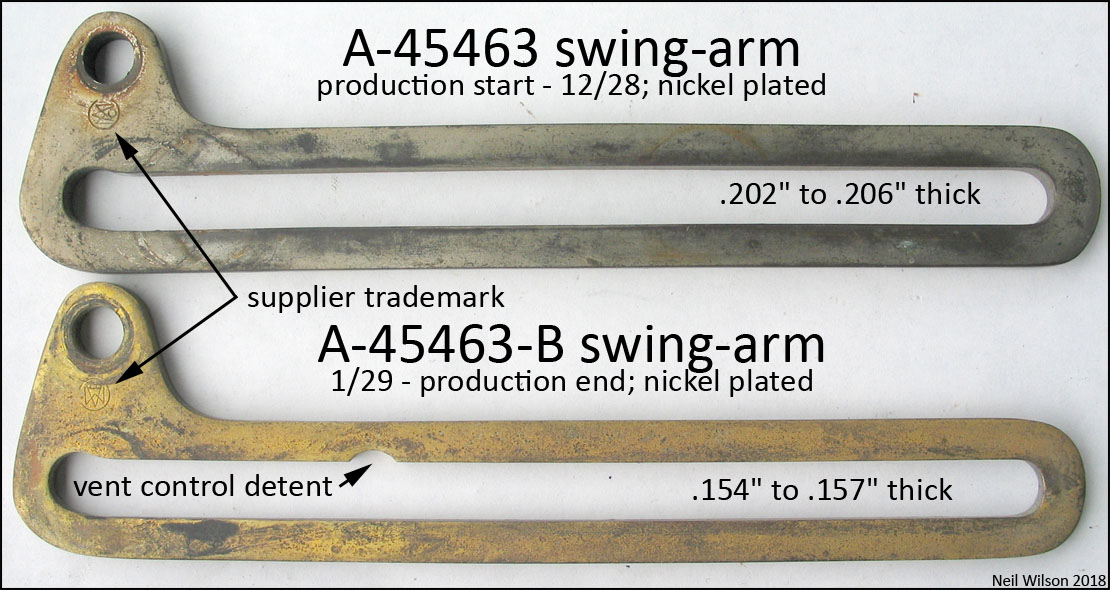

Swing-Arms A-45463 & A-45463-B

(used with windshield assembly A-79405)

The swing-arms and most of the fasteners were nickel plated.

The two swing-arms used with windshield assembly A-79405 d1-d7 are shown to the right. The 1928 A-45463 swing-arms did not have a detent (notch) in the slide. Starting January 1929, a detent was added. It was a venting stop to regulate the opening of the windshield. Therefore, it was likely designed to work with the 1-1/4″ wide flange of the A-45522 d4-d7 retainers. This was swing-arm A-45463-B.

Correct alignment of the swing arms require fitting which should be done before any other restoration to prevents paint and plating chipping/scratching. First, the windshield must be centered in the opening between the right and left hinge pillars. The swing-arm brackets (on the windshield frame and/or pillar) might require slight direction changes to get proper alignment and may require heating to make changes. The swing-arm brackets on the pillars need to have the Coupe pillar finish strips installed on each side of the windshield to properly fit the swing-arms. Note that, except for the 60-A Fordor, these swing-arms were used for all A and AA body types.

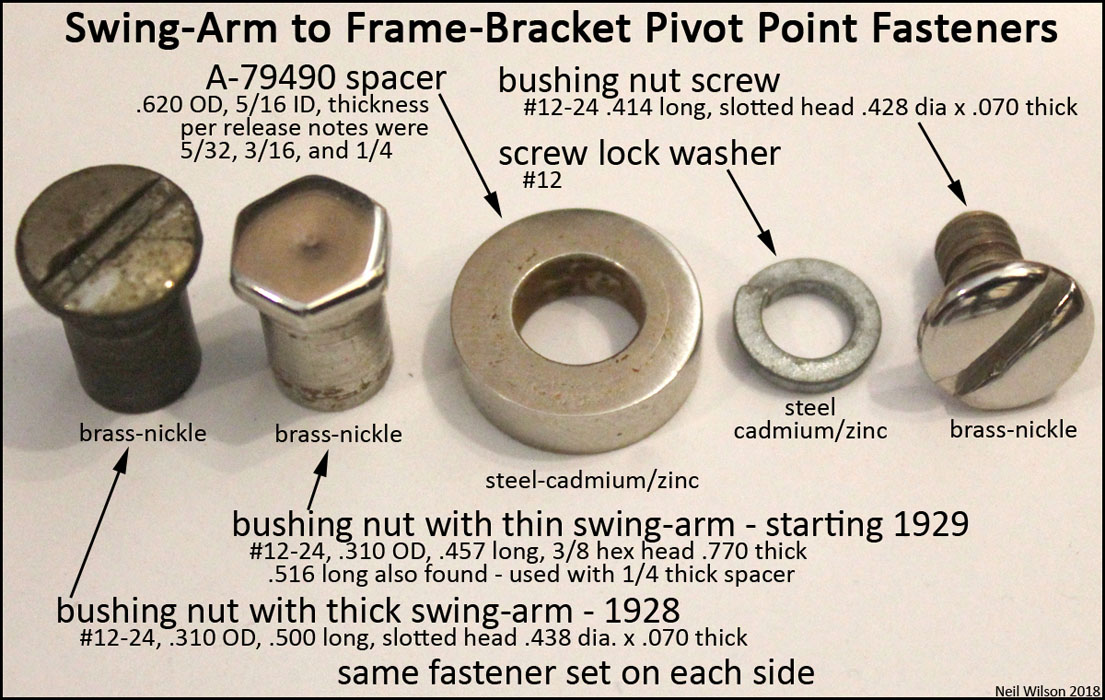

Swing-Arm to Windshield Pivot Point Fasteners

The pivot point for the swing-arms was at the swing-arm brackets riveted to the lower windshield frame as shown above. The installation sequence was:

- busing nut (head to outside of bracket)

- spacer

- swing-arm

- lock washer

- screw

With the screw tightened, the lock washer bottom-out on the end of the bushing nut and therefore left the swing-arm free to pivot. The spacer was needed for correct alignment of the swing-arm to the pillar. The photo to the right defines the pivot point fasteners used for each swing-arm thickness.

Note that the width of the windshield opening between hinge pillars for the 79-A Panel Delivery, 82-A Closed Cab, and 85-A Panel Delivery was slightly smaller than all other A-chassis body types. Consequently, for each side, the pivot point fasteners included spacer A-79490 and a unique length bushing nut. The nut length depended on the swing-arm thickness. The thick swing-arm was used for 1928 and, starting January 1929, the thin swing-arm was used (see photo above).

The bushing nuts observed for 1928 had slotted heads (i.e. vehicles with thick swing-arms). Vehicles observed starting 1929 used thin swing-arms and had bushing nuts with hex heads.

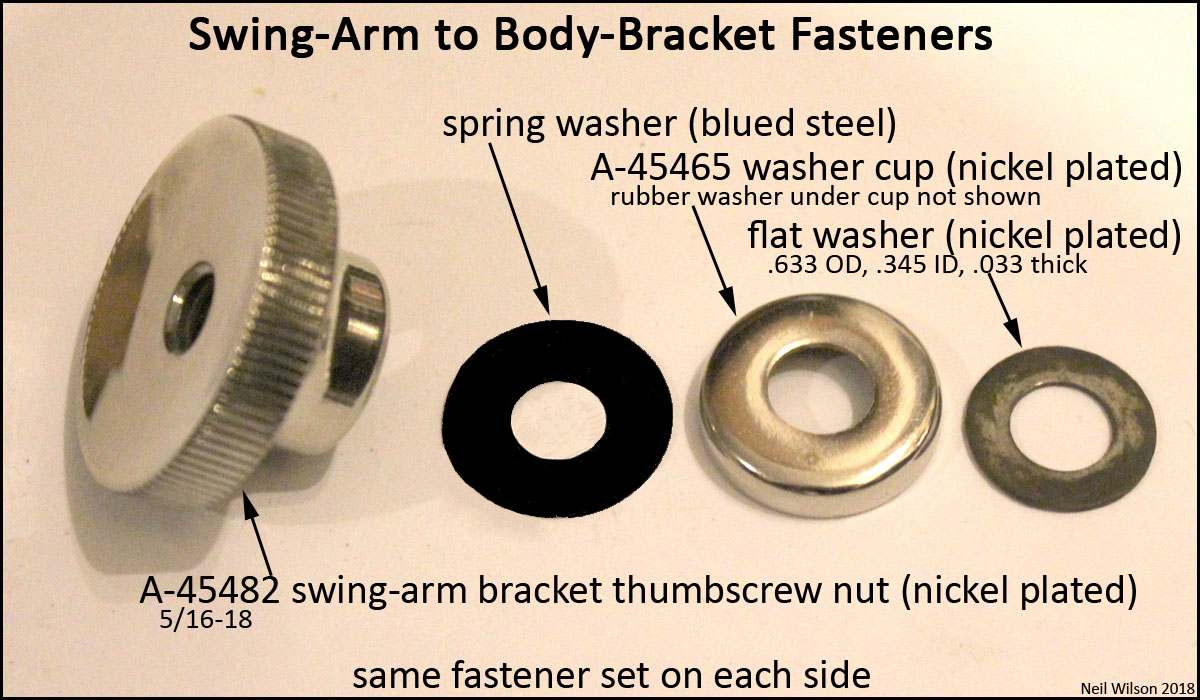

Swing-Arm to Body Pillar Fasteners

The photo to the right shows the swing-arm to body pillar fasteners (i.e. attachment to the on-body swing-arm bracket). The installation sequence was:

- flat washer

- swing-arm

- rubber washer

- washer cup

- spring washer

- thumbscrew nut

Note that the spring washer shown is not the real part. A real blued spring washer was not available for the shot. Also, the rubber washer for under the washer cup is not shown.

Windshield Parts List – A-79405

Windshield Assemblies AA-315405…upper/406…lower and Female Hinge AA-315510

Closed AA body type 315-A Standrive ???????????????. Under construction

Windshield Assembly AA-330405

Closed AA body type 330-A school bus and 330-B passenger buss ???????????????. Under construction.

Page Contents