2023/11/30 update

Page Contents

Inside Mirror Installations

AA’s with an open cab (76-A or 76-B) used the same mirror installation as was used for the A chassis with these same body types. Details of mirror brackets and mirror glass are found in the RGJS page 10-8. The 330-A School Bus and Passenger Bus used inside mirror AA-17704 (approximately 6″ high x 9″ wide) which was installed in an A chassis mirror bracket (which design not known). The 330-A Passenger Bus also came with a side view mirror.

Side View Mirror Installations

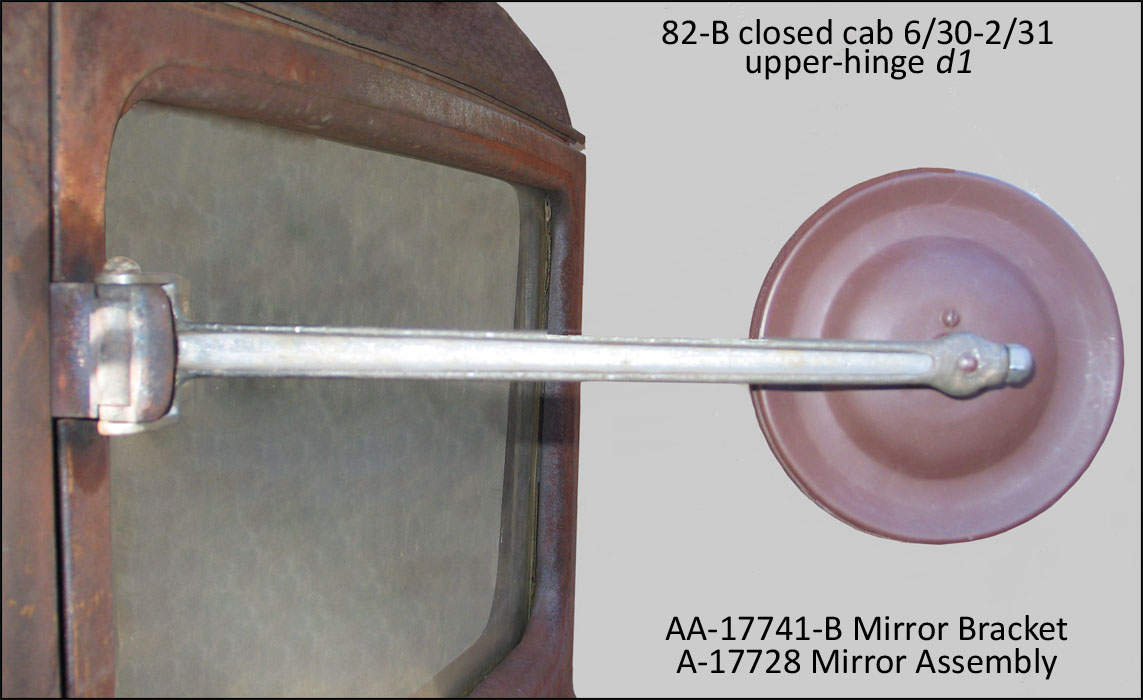

AA’s with a closed cab (82-A or 82-B) or those having a closed body came with a left side view mirror installation only. See the example photograph of this installation.

Note that nether a right side view mirror nor an interior rear view mirror was provided with these AA’s. The 330-A Passenger Bus was an exception and was supplied with both inside and left side view mirrors.

The table below identifies the left side view mirror installations (bracket and mirror combination) for closed bodies or for closed cab+cargo body combination.

Note that the Mirror-Installation-Location column has a direct bearing on the mirror bracket(s) used.

Mobile screen horizontal avoids scrolling

Side View Mirror Table

| Ford Model AA’s – Side View Mirror Table | ||||||

|---|---|---|---|---|---|---|

| AA Vehicle – Body or Cab+Cargo Body | Mirror Installation | |||||

| Type | Name | Cargo Body | Start End | Bracket | Mirror | Location |

| Neil Wilson 2018 | ||||||

| 82-A | Closed Cab | any cargo body or cab/chassis only | 12/27 er/28 | A 17737 d1 | A 17727 d1-d3 | hinge-pillar d1 |

| 82-A | Closed Cab | any cargo body or cab/chassis only | er/28 03/29 | A 17737 d2 | A 17727 d2-d4 | hinge-pillar d2-d3 |

| 82-A | Closed Cab | express (89-A) or cab/chassis only | 01/29 11/29 | A 17741 d1 | A 17728 | hinge-pillar d4-d5 |

| 82-A | Closed Cab | express (89-A) or cab/chassis only | 11/29 06/30 | A 17741 d2 | A 17728 | hinge-pillar d5 |

| 82-A | Closed Cab | platform (88-A) without racks | 01/29 09/29 | A 17741 d1 | A 17728 | hinge-pillar d4-d5 |

| 82-A | Closed Cab | platform (88-A) with racks (188-A, 134-A, 134-B) | 03/29 09/29 | AA 17745 | A 17728 | hinge-pillar d5 |

| 82-A | Closed Cab | platform (88-A) with or without racks | 09/29 06/30 | AA 17745 | A 17728 | hinge-pillar d5 |

| 82-B | Closed Cab | express (89-A, 195-A, 197-A), service (229-A), dump, garbage, coal, or cab/chassis only | 06/30 02/31 | A 17741-B | A 17728 | upper hinge d1 |

| 82-B | Closed Cab | platform (88-A, 185-A or 185-B) with or without racks | 06/30 02/31 | AA 17745-B | A 17728 | upper hinge d1 |

| 82-B | Closed Cab | service (229-A) cab/chassis only | 03/31 end | A 17742-B | A 17723-B | upper hinge d2 |

| 82-B | Closed Cab | express (195-A, 197-A, 239-A, or 242-A), dump, garbage, or coal (except 201-B) | 03/31 end | AA 17745-C | A 17723-B | upper hinge d2 |

| 82-B | Closed Cab | platform (185-B or 187-A) with or without racks, or coal (201-B) | 03/31 04/31 | AA 17745-C | A 17723-B | upper hinge d2 |

| 82-B | Closed Cab | platform (185-B or 187-A) with or without racks, coal (201-B), or grain (248-A or 244-A) | 05/31 end | AA 17698 | A 17723-B | upper hinge d2 |

| 85-A | Panel Delivery | 08/28 03/29 | A 17737 d2 | A 17727 d3-d4 | hinge-pillar d2-d3 | |

| 85-A | Panel Delivery | 01/29 11/29 | A 17741 d1 | A 17728 | hinge-pillar d4-d5 | |

| 11/29 06/30 | A 17741 d2 | A 17728 | hinge-pillar d5 | |||

| 85-B | Panel Delivery | 06/30 02/31 | A 17741-B | A 17728 | upper hinge d1 | |

| 03/31 end | A 17742-B | A 17723-B | upper hinge d2 | |||

| 210-A | Panel Delivery | 03/31 08/31 | AA 17697 | A 17723-B | upper hinge d2 | |

| 09/31 end | AA 17697-B | A 17723-B | upper hinge d2 | |||

| 270-A | Funeral Service | er/31 end | A 17742-A | A 17723-A | upper hinge d2 | |

| 275-A | Funeral Coach | er/31 end | A 17742-A | A 17723-A | upper hinge d2 | |

| 280-A | Ambulance | er/31 end | A 17742-A | A 17723-A | upper hinge-d2 | |

| 285-A | DeLuxe Police Patrol | er/31 end | A 17742-A | A 17723-A | upper hinge d2 | |

| 290-A | Standard Police Patrol | er/31 02/31 | A 17741-B | A 17728 | upper hinge d1 | |

| 03/31 end | A 17742-B | A 17723-B | upper hinge d2 | |||

| 300-A | DeLuxe Delivery | 02/31 end | A 17742-A | A 17723-A | upper hinge d2 | |

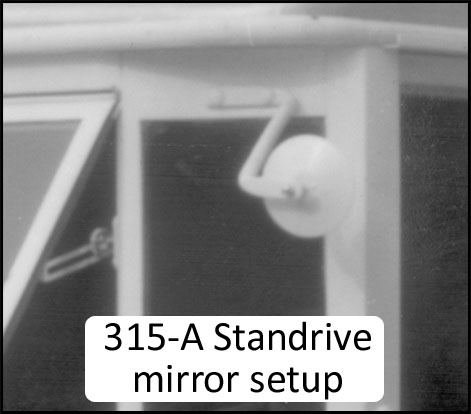

| 315-A | Standrive | 08/31 end | unidentified | A 17723-B | front header | |

| 330-A | Passenger Bus | er/31 end | AA 334478 | AA 331476 | unknown | |

| AAAAA | ||||||

Mirror Brackets – Hinge-Pillar Installed

There were five mirror brackets use for installation on the left hinge-pillar – each was dipped, gloss-black, enamel finished.

Hinge-Pillar Designs

For the 82-A closed cab and the 85-A panel delivery, the mirror bracket was installed on the left hinge-pillar at one of several locations depending on the design of this pillar (i.e. part A-79356 coupe pillar). There were five left hinge-pillar designs. Each design dictated the mirror bracket(s) that was used and its location. There was some production date overlap of the hinge-pillar designs.

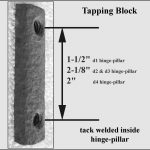

The hinge-pillar designs had a tapping block or D-nuts installed to receive the mirror bracket fasteners. Hinge-pillar d1, d2, and d4 had a tapping block (i.e. threaded bar) tack welded to the inside of the pillar. Hinge-pillar d3 had either a tapping block or D-nuts installed. Hinge-pillar d5 had D-nuts installed. A sample tapping block is shown in the gallery below.

Note – Some AA restoration projects are put together without the original 82-A or 85-A body. Consequently, the hinge-pillar design may not match up with the intended month/year of the project. For example – a September 1929 AA project with a June 1928 82-A closed cab will have the wrong hinge-pillar for the project. The hinge-pillar would need to be changed to the correct design if originality is desired.

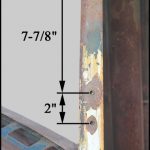

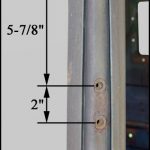

Left Hinge-Pillar Designs Gallery – 79-A Panel Delivery, 82-A Closed Cab, 85-A Panel Delivery

- Hinge-Pillar d1 – 12/27-er/28

- Hinge Pillar d2 -er/28-3/29

- Hinge Pillar d3 -er/28-3/29

- Hinge Pillar d4 -er/29

- Hinge Pillar d5 -er/29-6/30

- Tapping Block

Mirror Brackets – with Hinge-Pillar d1-d3

A-17737 d1-d2

These brackets were assemblies consisting of a ball stud swaged to the mirror bracket. They are shown in the photograph below which includes details like usage, length, fasteners, etc.

Note: The d1 bracket was not available through Ford service. Due to fastener hole spacing, the d1-d2 assemblies were not compatible. Normally, Ford would have assigned part suffixes to identify these two parts (like “B” to the new part and “A” or “AR” to the old part). However, for service, a d1 bracket would have been replaced with the design 2 and installed at the sun visor.

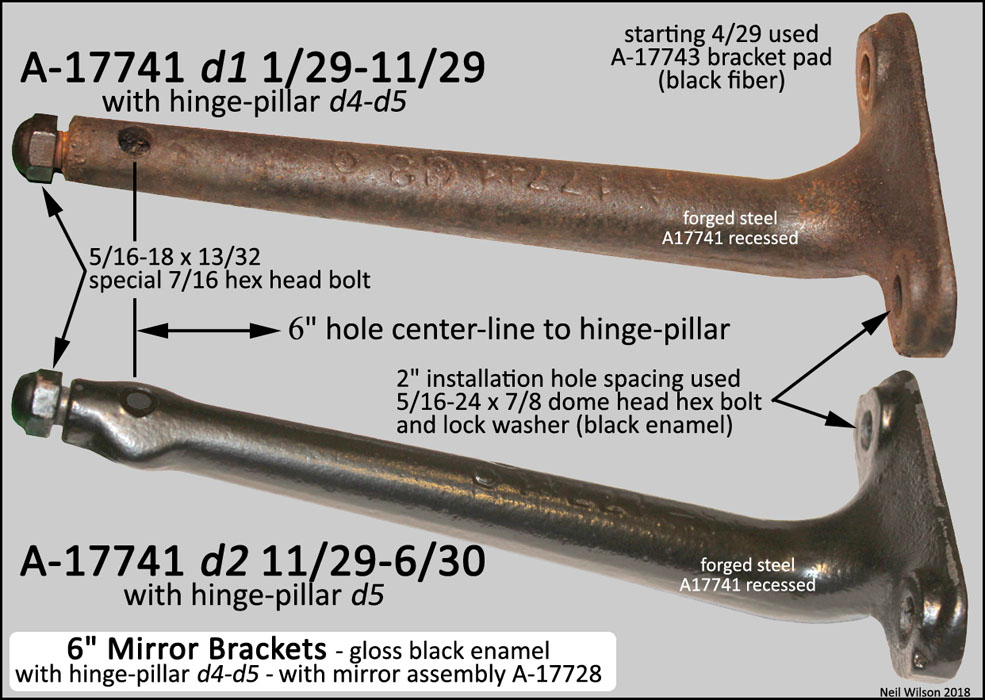

Mirror Brackets – with Hinge-Pillar d4-d5

A-17741 d1-d2

These forged steel mirror bracket designs are shown in the photograph below which includes details like usage dates, length, fasteners, etc. (see table for cargo body requirements). See hardware details below.

Note: These two mirror bracket designs were the same except for the enlarged section around the mirror stud installation hole. The recessed A17741 part id was on the side facing the rear of the vehicle and orientated upside down. These mirror brackets were also used for the A chassis with body types 82-A, 79-A, 130-A, 135-A, and 150-A. Refer to the RGJS Area 10 for details.

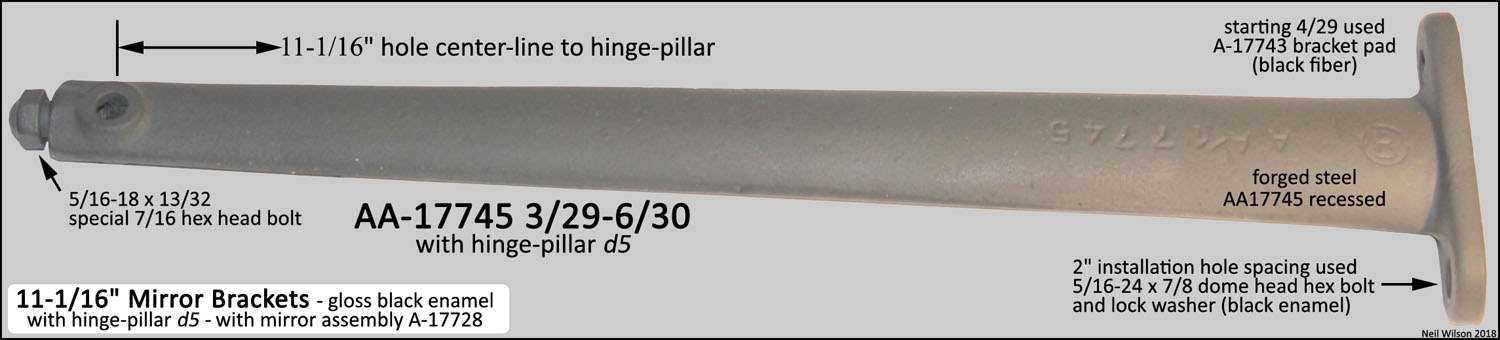

AA-17745

3/29-6/30 (see table for cargo body requirements) – An 11-1/16″ long, forged steel, mirror bracket installed to the D-nuts of left hinge-pillar d5. It may have also been used on those AA’s with hinge-pillar d4. See hardware details below.

AA-17741 d1-d2 and AA-17745 Mirror Bracket Hardware Details

The bracket to body fasteners were two 5/16-24 x 7/8 dome headed hex bolts and lock washers (black enamel). Starting in April of 1929 a black fiber pad was used between the bracket and pillar.

There was a 5/16-18 x 13/32 special 7/16 hex head clamping bolt on the outer end of these brackets which was used to clamp the mirror assembly to the bracket.

Mirror Brackets – Upper-Hinge Installed

Starting in June 1930 the new 82-B closed cab and the 85-B panel delivery body types began production. The two different mirror brackets for these new body types were installed on the left, upper door-hinge. This same door-hinge location was used for additional closed body types introduced starting in early 1931. Starting March 1931 new mirror brackets were introduced which replace the prior brackets. The 315-A Standrive and 330-A Passenger Bus were the only exceptions to this side view mirror bracket location.

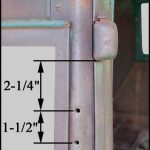

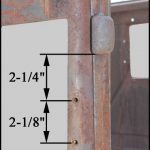

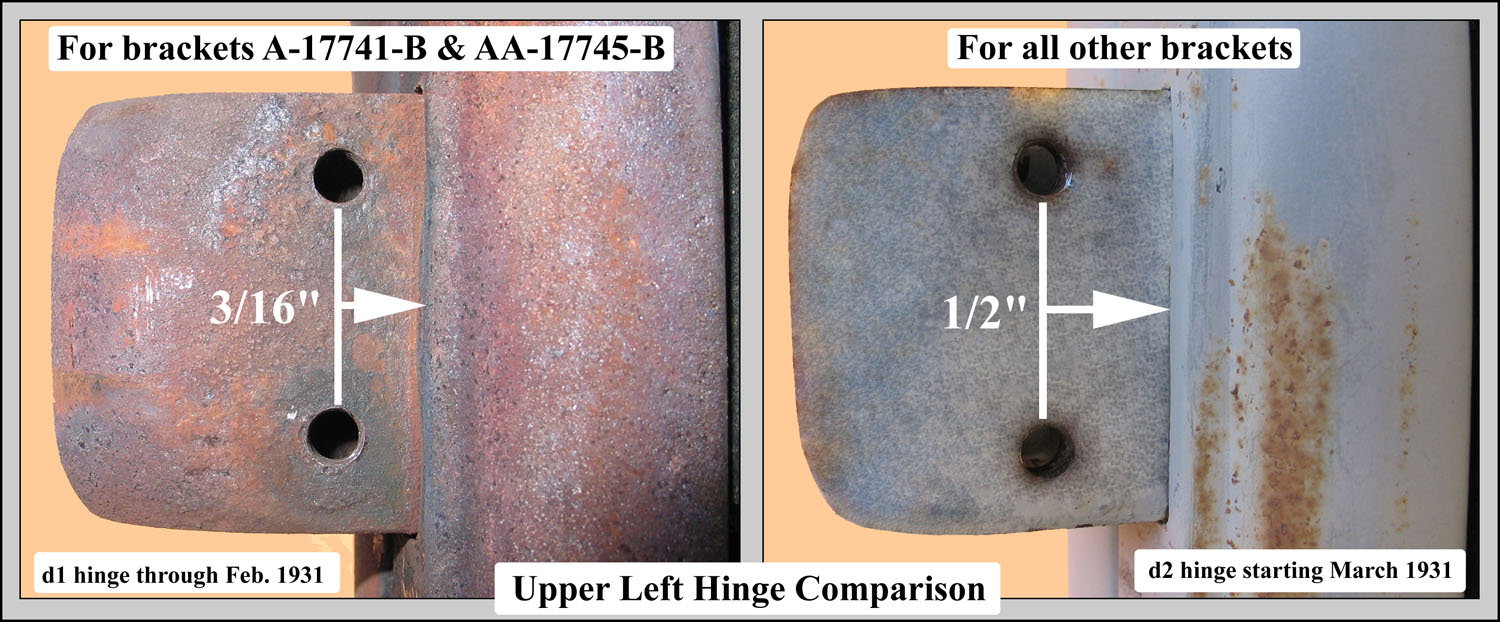

Upper-Hinge Designs

There were two left, upper-hinge designs. The design dictated which mirror bracket(s) was used. The design 1 left, upper-hinge had a 3/16″ spacing between the door and the two threaded holes for bracket-to-hinge screws. For the design 2 left, upper-hinge the spacing was 1/2″.

Doors for the 270-A Funeral Service, 275-A Funeral Coach, 280-A Ambulance, 285-A De Luxe Police Patrol, 300-A De Luxe Delivery body types had the d2 hinge. Some of these body types started production as early as January 1931.

Note – Some AA restoration projects are put together without the original doors, cab or body. Consequently, the left, upper-hinge design may not match up with the intended month/year of the project. For example – a September 1931 AA project with doors from a June 1930 82-B closed cab will have the wrong left, upper-hinge design for the project. The location of the threaded holes in the hinge for an original mirror bracket would need to be changed if originality is desired.

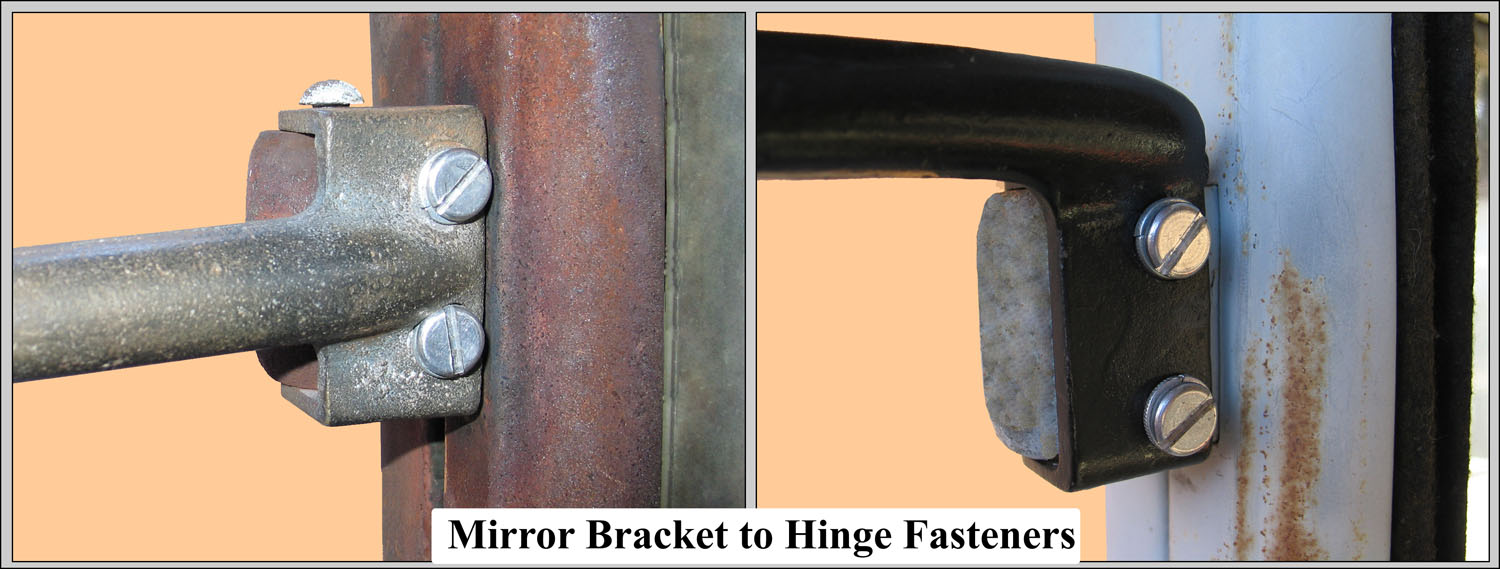

Upper-Hinge Mirror Bracket to Hinge Fasteners

These brackets fit over the left, upper hinge and were held in place with a 2” long hinge pin. There were two threaded holes in the hinge. Two special headed machine screws and lock washers secured the bracket to the hinge preventing the bracket from moving forward. These fasteners were as follows:

1 – A-80280-A – Pin (mirror bracket to hinge) 2” – black

1 – A-80280-B – Pin (mirror bracket to hinge) 2” – chrome (with chrome plated bracket A-17742-A)

2 – A-20428-S3 – screw (mirror bracket to hinge) #12-24 (3/8) special head screw (.435” head) – black

2 – A-22139-S3 – washer (mirror bracket to hinge screw) 7/32 (1/16 x 27/64) lock washer (tangleproof) – black

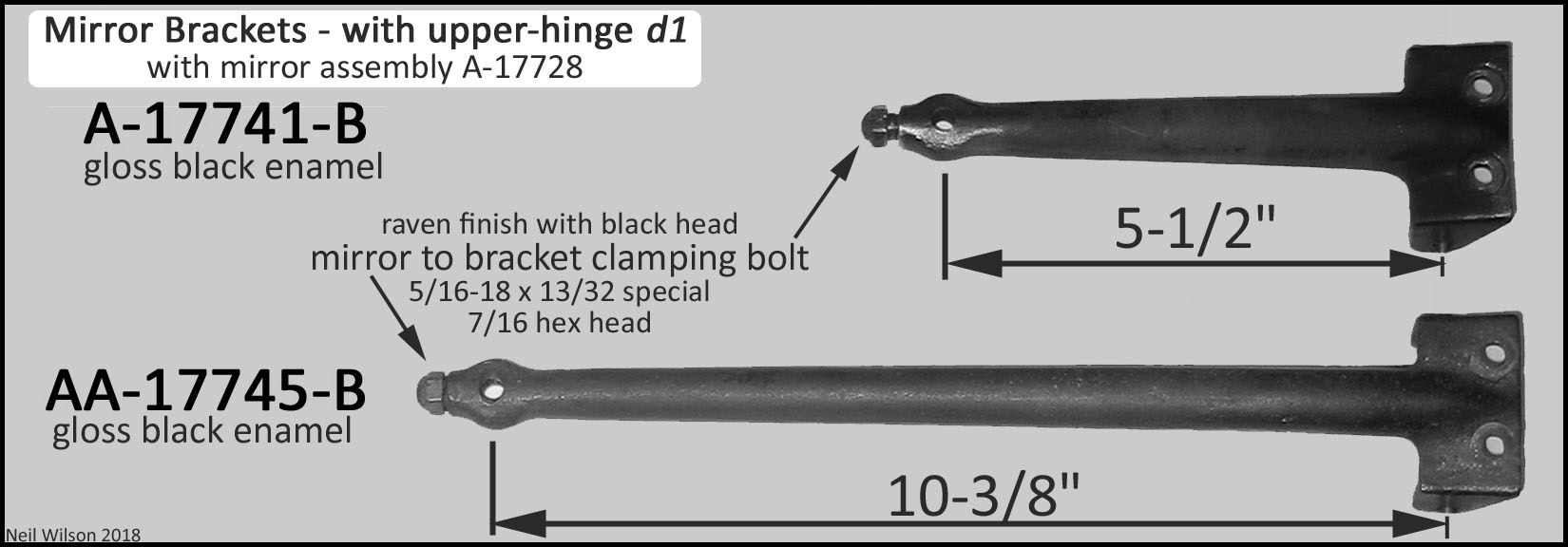

Mirror Brackets – with Upper-Hinge d1

A-17741-B and AA-17745-B

In June 1930 the 82-B closed cab and 85-B panel delivery replaced the prior 82-A and 85-A body types. This marked the beginning of the two left, upper-hinge installed mirror brackets shown below. When the standard police patrol (type 290-A) was first introduced, it used the A-17741-B mirror bracket. Starting 3/31, the d2 upper-hinge was the standard, therefore these two brackets were replaced.

Refer to the “Side View Mirror Table” for bracket usage on 82-B Closed Cab by cargo body type.

The clamping bolt was the same as was used for the prior brackets (raven finished with black painted head). Bracket-to-Hinge Fasteners details are provided above.

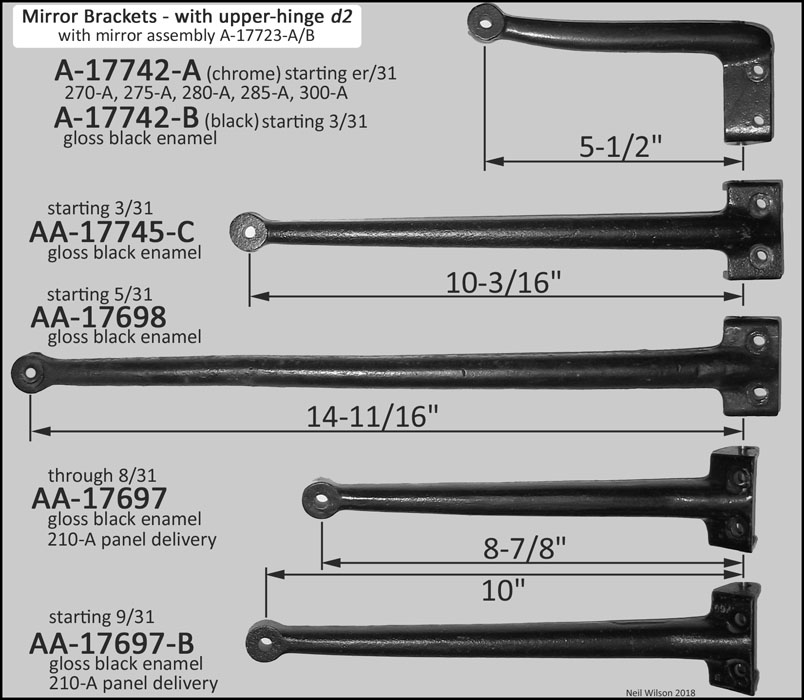

Mirror Brackets – with Upper-Hinge d2

The six mirror brackets which were installed on the design 2, left, upper-hinge are shown below. Starting early 1931, the chrome plated A-17742-A bracket was use for closed body types 270-A, 275-A, 280-A, 285-A, and 300-A along with the chrome plated A-17723-A mirror assembly. Starting 3/31, other body types were converted to the d2 upper-hinge. These body types used the gloss black enamel brackets and A-17723-B black enamel mirror assembly.

Refer to the “Side View Mirror Table” for bracket usage on 82-B Closed Cab by cargo body type. Bracket-to-Hinge Fastener details are provided above.

Mirror Brackets – Unidentified

The 315-A Standrive used a double bent mirror bracket (part unknown) along with the A-17742-B mirror assembly. Both the bracket and mirror were painted body color (see the photograph to the right).

The 330-A passenger bus used side mirror bracket AA-334478 (no engineering drawing is listed). Mirror AA-331476 is listed as “Side Pillar Mirror”. The engineering drawing has not been looked at.

Mirror Assemblies

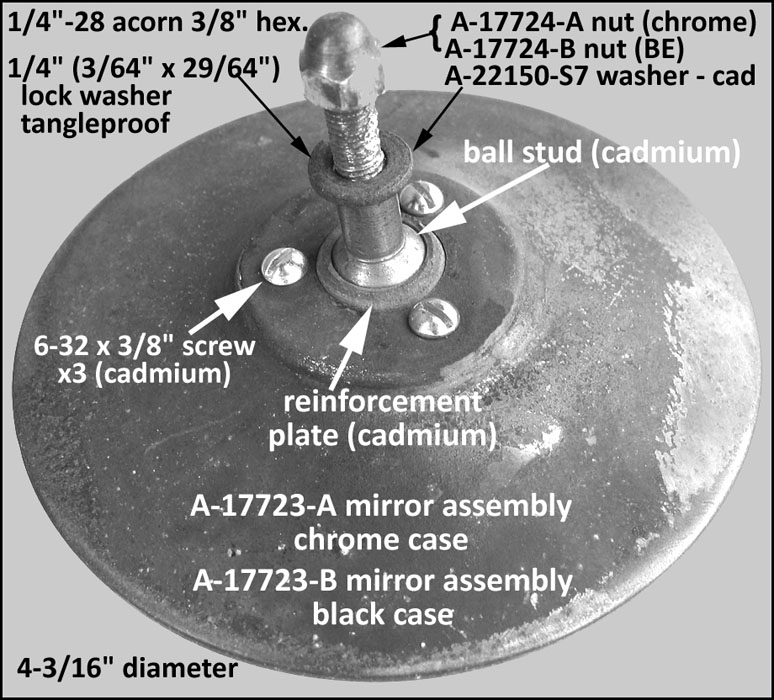

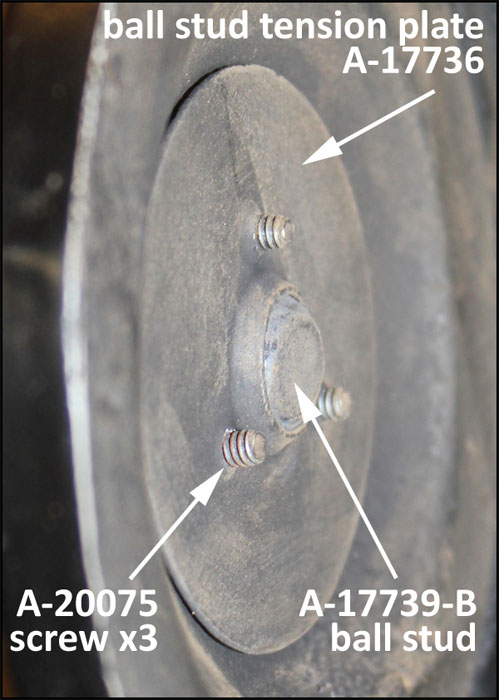

A-17723-A/B Mirror Assemblies

er/31-production end – These mirror assemblies were introduced in 1931 with two case finishes – chrome (assembly A-17723-A) and black enamel (assembly A17723-B). The body type dictated which mirror Ford provided as indicated in the Side View Mirror Table. These assemblies were used with the six upper-hinge mirror brackets which did not have a mirror clamping bolt on the outer end. The gallery shows parts and finishes.

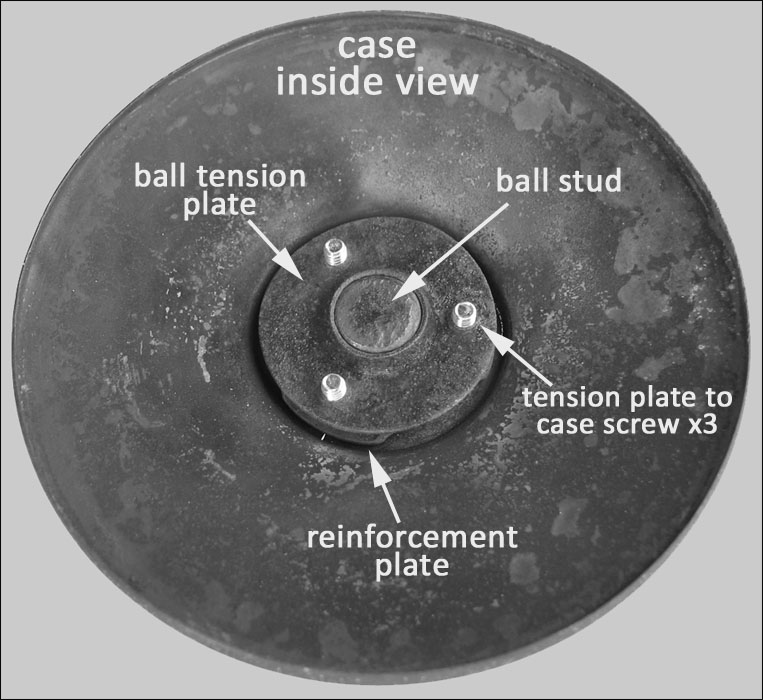

Inside of the case, there was ball/case reinforcement plate. The ball stud was inserted though this plate. A ball tension plate was located at the ball end of the stud and was secured with three screws (heads on the outside of the case).

A-17723-A/B Mirror Assembly Gallery

- A-17723-B Mirror Assembly – external view

- A-17723-B Mirror Assembly – internal view

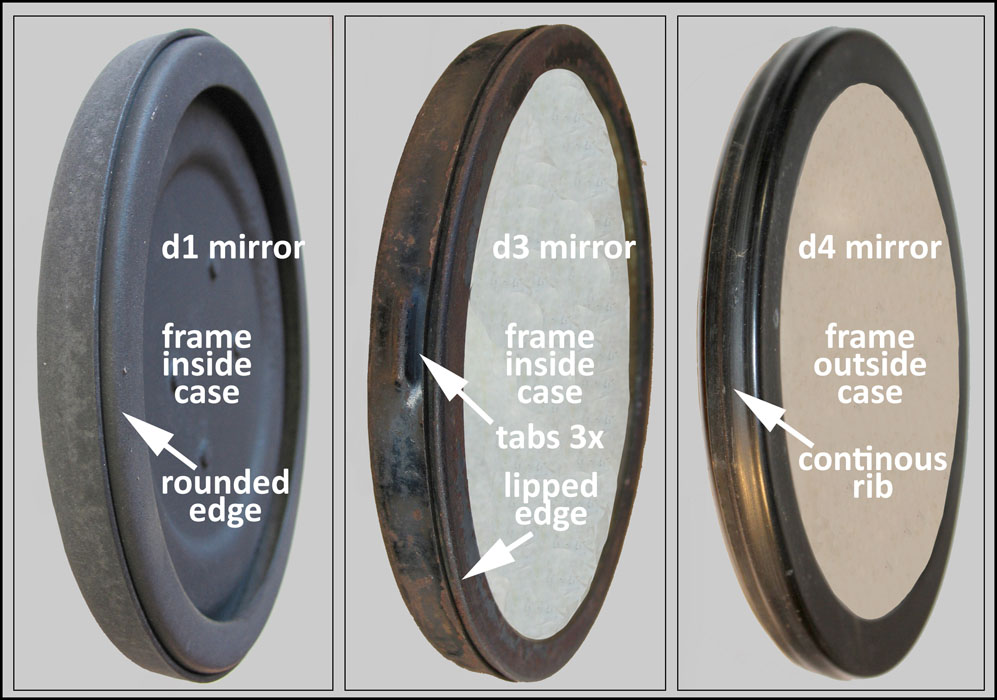

A-17727 d1-d4 Mirror Assemblies

These four mirror assemblies were used with A-17737 d1-d2 mirror bracket assemblies which included a ball stud swaged to the mirror bracket.

A-17727 d1 Mirror Assembly

12/27–10/28 – Both an engineering drawing and originals have been found for this d1 assembly. The mirror retainer frame was a press fit into the inside of the mirror retainer case. Refer to the left image in the retainer frame photograph. It was designated obsolete in Oct. 1928.

Note: At production start, this d1 mirror assembly was designated for the “A Panel Del” (+ AA Cab and AA Panel Del). Therefore the part id had an “A” prefix. The panel deliveries did not start production until August 1928. Consequently, only the AA Cab used this d1 mirror assembly until early April when the closed cab became available on the A chassis. Beginning in March 1928 this d1 assembly’s internal factory part number was changed to A-17727-A1 and the assembly’s clamps, case and frame parts were given “A” suffixes.

A-17727 d2 Mirror Assembly

3/28-12/28 – Only engineering drawings have been found for this d2 assembly (no originals found). The mirror retainer frame was pressed onto the outside of the mirror retainer case. The frame and case each had three 1/2″ long stamped index tabs around their perimeters to hold the frame after being pressed over the case. This d2 assembly was designated obsolete in December 1928.

Note: This assembly carrier A-17727-A2 as the internal factory part id. The assembly’s clamps, case and frame were given part ids with “B” suffixes to distinguish these parts from the “A1” assembly.

A-17727 d3 Mirror Assembly

3/28-12/28 – Only one original has been found (no engineering drawing found). It is assumed that this assembly was produced concurrently with the d1 and d2 assemblies. It had a retainer frame which fit inside the retainer case (see Retainer Frames photograph above). The frame had a lip which covered the edge of the case. There were three 1/2″ long stamped index tabs which held the frame after being pressed into the case. Refer to the center image in the retainer frame photograph.

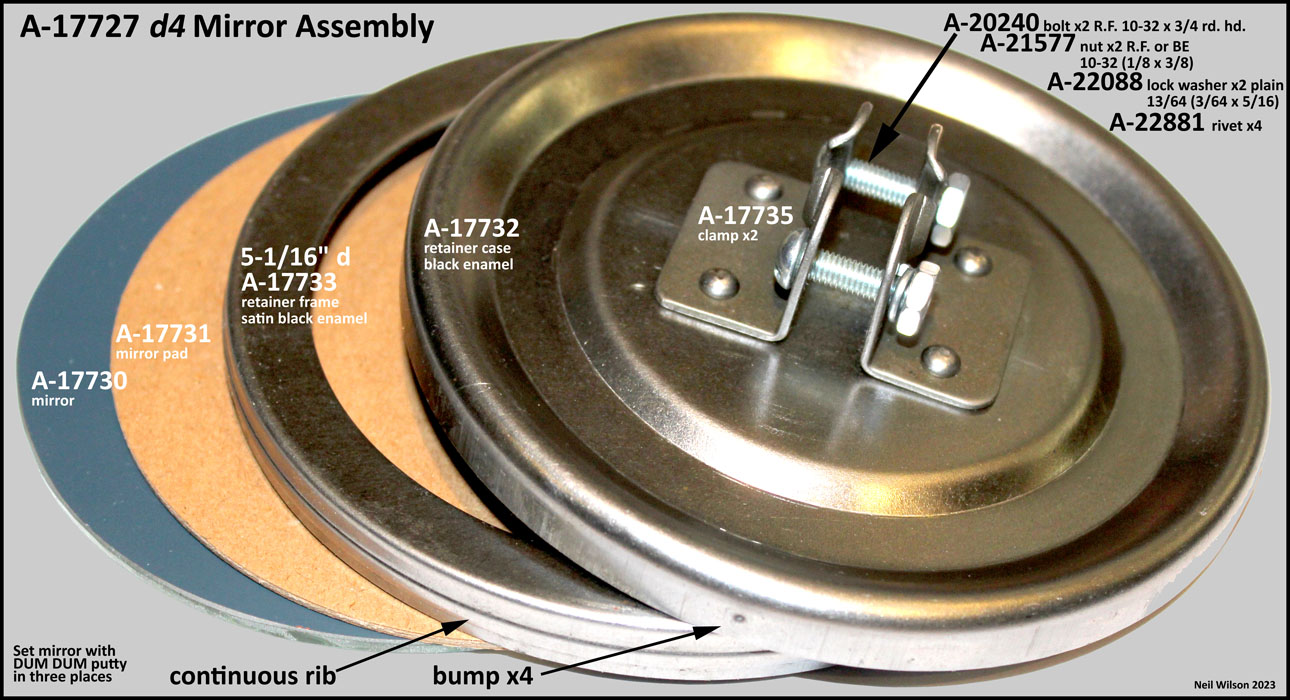

A-17727 d4 Mirror Assembly

mid/28 – 3/29 – The usage date range is based on observations. Only originals of this d4 assembly have been found (no engineering drawing found). It is the most common mirror assembly found. It appears to be the design used on Ford archive AA photographs dated 2/29. Since the prior designs were designated obsolete by 12/28, it is assumed that this assembly was used through 3/29 for those 79-A panel delivery, 82-A closed cab, and 85-A panel delivery vehicles with hinge-pillar d2 and d3. This assembly had a retainer frame which pressed over the retainer case (see Retainer Frame photograph above). The case had four small bumps around its perimeter. These bumps fit into a continuous rib around the perimeter of the frame. Refer to the right image in the retainer frame photograph. The frame was the same design as was used on subsequent mirror assembly A-17728 (used for hinge-pillar d4 and d5).

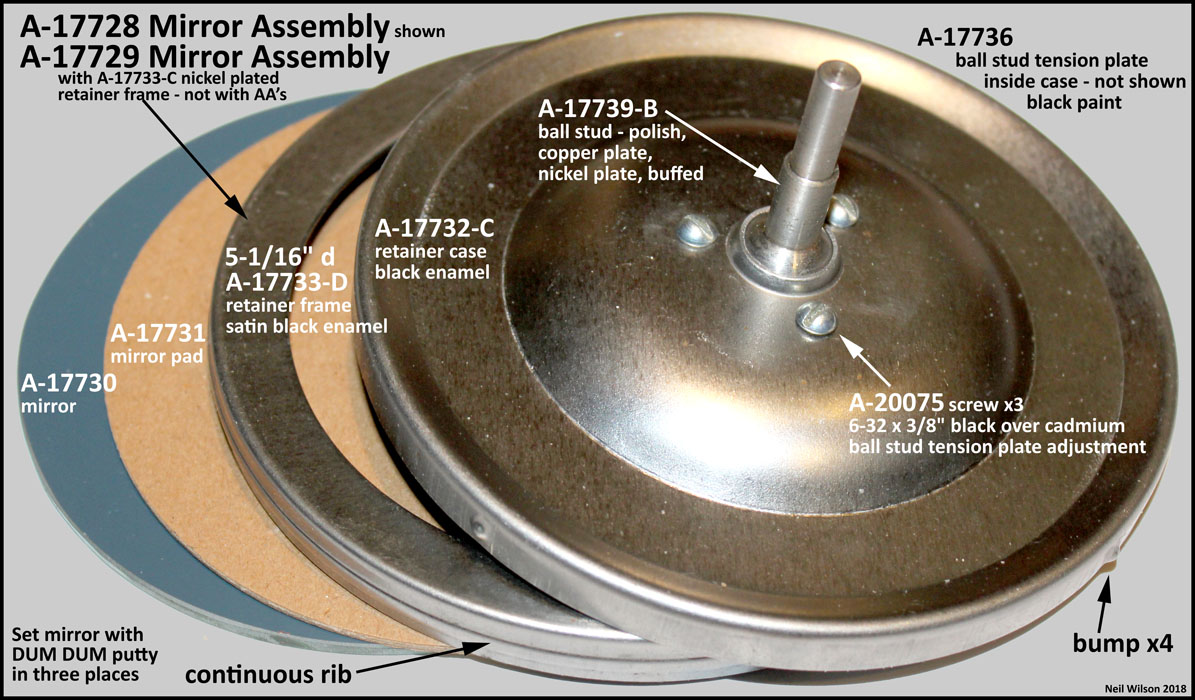

A-17728 Mirror Assembly

1/29-2/31 – Both originals and engineering drawings have been found for this assembly. It had a ball stud which passed through from the inside of the case. It was used with the five mirror brackets which had a mirror clamping bolt on the outer end (these included the three d4-d5 hinge-post installed brackets and the two d1 upper-hinge installed mirror brackets).The retainer frame was the same as the frame for A-17727 d4 mirror assembly with a continuous rib around the outer flange. The case had four bumps around its perimeter to hold the frame after being press over the outside of the case.

A ball tension plate held the ball stud from inside of the case. Three screws, with their heads visible on the outside of the case, were used to adjust the tension.

Note: Assembly A-17728 was initially A-17729 until March 1929. At which time, A-17729 mirror assembly was fit with a nickel plated retainer frame which was only used with A chassis body types.

..

Page Contents